What People Mean When They Ask “Safe”

People ask if polypropylene fibers are safe because these fibers touch many parts of a job. A buyer cares about health and risk and brand trust. A contractor cares about what workers breathe and touch. A spec writer cares about rules and long term behavior. A building owner cares about fire performance and service life.

Polypropylene is a common plastic, and many industries use it at scale. In construction, many teams use polypropylene fibers in concrete for crack control and toughness and better finish results. Many tunnel and slab projects also use polypropylene fibers for fire related spalling control, and this use is common in guidance documents and technical papers.

Safety depends on the stage you look at. A fiber in a bag is not the same as a fiber locked inside cured concrete. This is why the best answer needs both views. Ecocretefiber™ supplies concrete grade fibers, and Shandong Jianbang Chemical Fiber Co., Ltd. supports buyers with stable supply and clear use guidance.

Material Safety in Plain Terms

Polypropylene is a solid polymer. It is not a volatile liquid. It does not act like a solvent or an acid. Under normal storage and use, polypropylene is stable, and most safety notes focus on irritation and dust instead of chemical poisoning. Many polypropylene and fiber safety data sheets describe dust and mechanical irritation as key practical risks.

Still, “safe” never means “careless.” A fast pour can make dust. A fast mixing step can make fibers fly. A hot source can melt plastic and make fumes. Dust build up can also create a fire risk in the right conditions, so a team should control dust and keep good housekeeping.

Ecocretefiber™ focuses on clean packing and stable fiber shape, and this helps teams dose fibers with less mess and less waste.

What Big Rule Systems Suggest

Many safety questions get easier when you look at where the same base material already appears. Polypropylene shows up in food contact rules, and those rules exist because regulators treat migration and exposure as real topics. In the United States, 21 CFR § 177.1520 says olefin polymers listed in the rule may be safely used as articles or parts of articles intended for contact with food, under the conditions in the section. In the European Union, Commission Regulation (EU) No 10/2011 sets a full system for plastic materials and articles intended to come into contact with food, and it gets regular updates through consolidated versions. EFSA also explains how food contact risk work focuses on what can move from a material into food, and how toxicology and exposure drive the result. These systems do not mean every fiber product is “approved” for every use, and additives still matter. Still, these systems show that polypropylene is not a new or unknown material, and that helps buyers feel more confident when they also follow the SDS and local site rules.

Handling Safety for Workers and Plant Teams

Most risk shows up during handling, not after curing. A bag of fibers can shed lint and fine dust. A mixing action can move a few fibers into the air for a short time. Some cutting or grinding operations on plastic parts can also create dust.

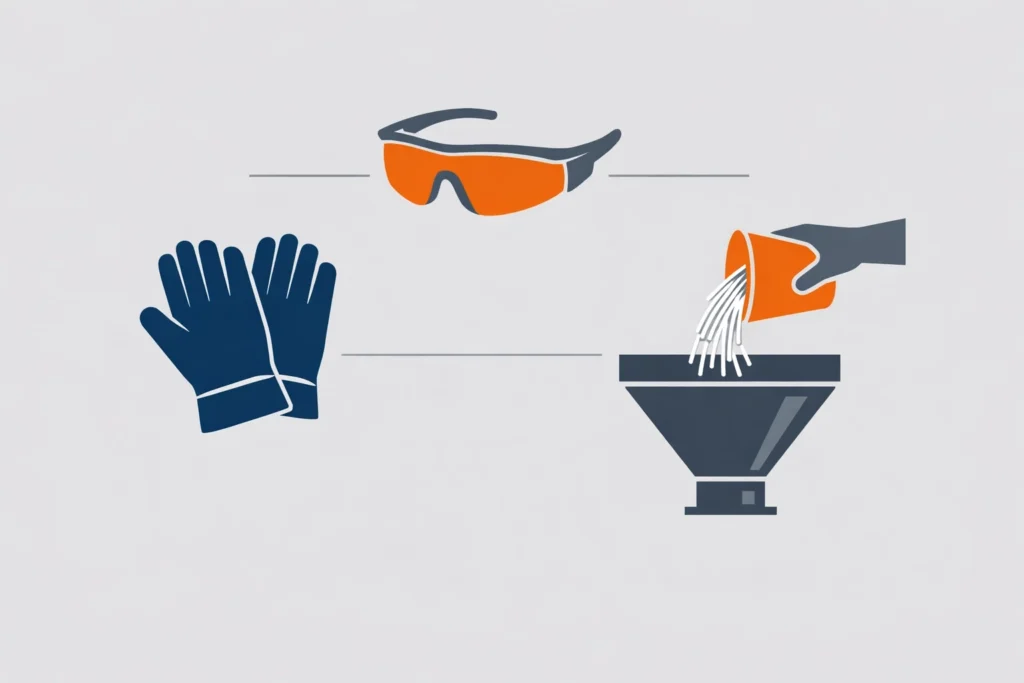

Many SDS documents give the same basic controls. A site should use good ventilation. A site should avoid breathing dust. A site should use eye protection when dust can form, and a site should use gloves when abrasion can happen.

A site can also use exposure limits as a simple reference point for “general dust.” OSHA’s annotated PEL table lists “total dust” and “respirable fraction” values used for particulates not otherwise regulated. NIOSH also lists the same category and notes irritation symptoms for eyes and skin and throat and upper airways. Teams still need local rules, and teams should use the SDS for the exact product they buy.

Dust, Irritation, and Simple Controls That Work

A worker may think polypropylene fibers look harmless, and a worker still needs controls because dust and lint can irritate eyes and airways. OSHA lists “total dust” and “respirable fraction” values in its annotated PEL table, and many safety teams use these as a baseline for general dust control when a dust has no specific limit. NIOSH also lists the same category in the Pocket Guide and it names common symptoms like irritation of eyes and skin and throat and upper respiratory system. Many polypropylene SDS documents say cutting or sawing or grinding can raise nuisance particles that can cause mechanical irritation to skin and eyes and the respiratory tract, so the safest plan is to prevent dust when possible. This is why a simple plan works well: a team keeps bags closed until use and pours slowly, and a team uses local exhaust or good open air mixing where possible, and a team cleans with a vacuum system instead of dry sweeping. A team also trains crews to wash hands after handling and to keep food and drink away from dusty areas.

Safety After Fibers Enter Concrete

Safety changes after mixing. Concrete locks fibers inside a cement matrix after curing. The fibers stop being a loose dust source. The fibers also stop being a direct touch material for most users. This is one reason why fiber reinforced concrete can be a low contact solution in daily building use.

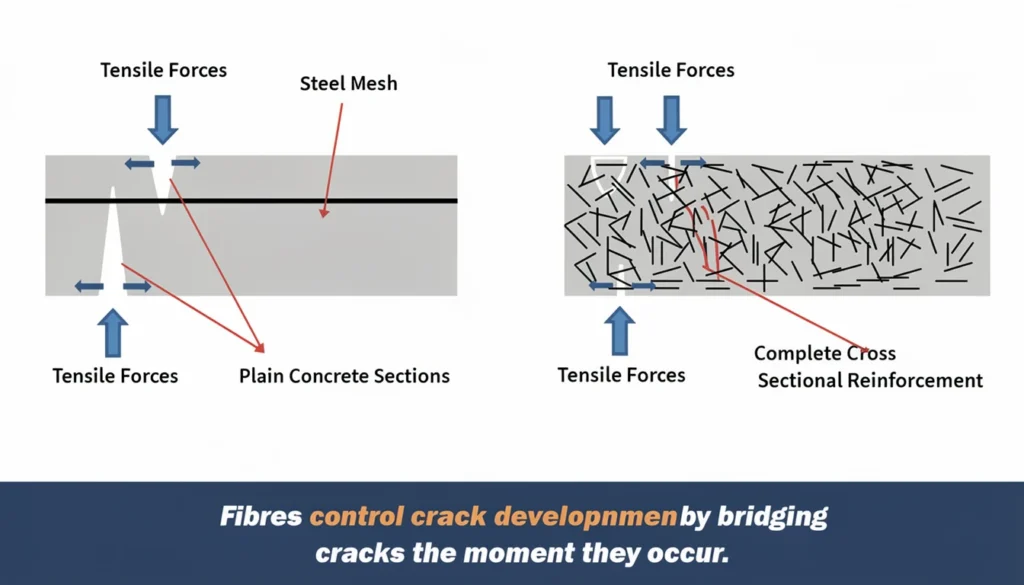

Polypropylene fibers can also support safety in a different way. In some fire exposures, concrete can spall, and this can create a sudden hazard. Research work and technical papers report that polypropylene fibers can reduce spalling risk because fibers melt and help pressure release paths form.

A project team should still treat cutting and grinding of cured concrete as a concrete dust issue. Silica control is a separate and serious topic. Fibers do not remove the need for standard dust controls.

Fire, Spalling, and Why PP Fibers Can Improve Safety Outcomes

Concrete can spall in a fire when heat drives water into vapor, and pressure builds inside dense concrete. Researchers have reviewed this behavior, and they report that adding polypropylene fibers often reduces spalling risk in fire exposure. Technical guidance also explains that polypropylene monofilament microfibres are used to counteract explosive spalling in cast concrete and shotcrete, and the guidance explains that fiber design and dosage matter for results. Newer studies still test the same idea in different cement systems, and they report that polypropylene fibers can create connected paths for vapor to escape during rapid heating, and that spalling is reduced in those tests. A buyer can connect this to “safe” in a direct way. The fiber does not only help with cracks and finish. The fiber can also support passive safety under high temperature events when the design fits the risk. A spec still needs local code checks and project testing, and Ecocretefiber™ supports that work with consistent fiber geometry and steady quality.

Toxicity and Cancer Questions

Some people worry about cancer when they hear “plastic fiber.” The question is fair, and the answer needs careful wording.

IARC and related summaries list polypropylene as Group 3, which means it is not classifiable as to its carcinogenicity to humans, based on the evidence set IARC used. IARC summaries also discuss that some tests involved implantation in animals, and that setup is not the same as normal workplace exposure. Many SDS documents also describe polypropylene polymers as low toxicity by common exposure routes, and they focus more on irritation from dust and hot melt burns from molten material.

A fire changes the situation because burning materials can create smoke that is unsafe to breathe. A project should treat fire smoke as hazardous in general. This is true for many building materials. A good fire plan and good ventilation planning still matter.

Environmental Safety and Microplastic Concerns

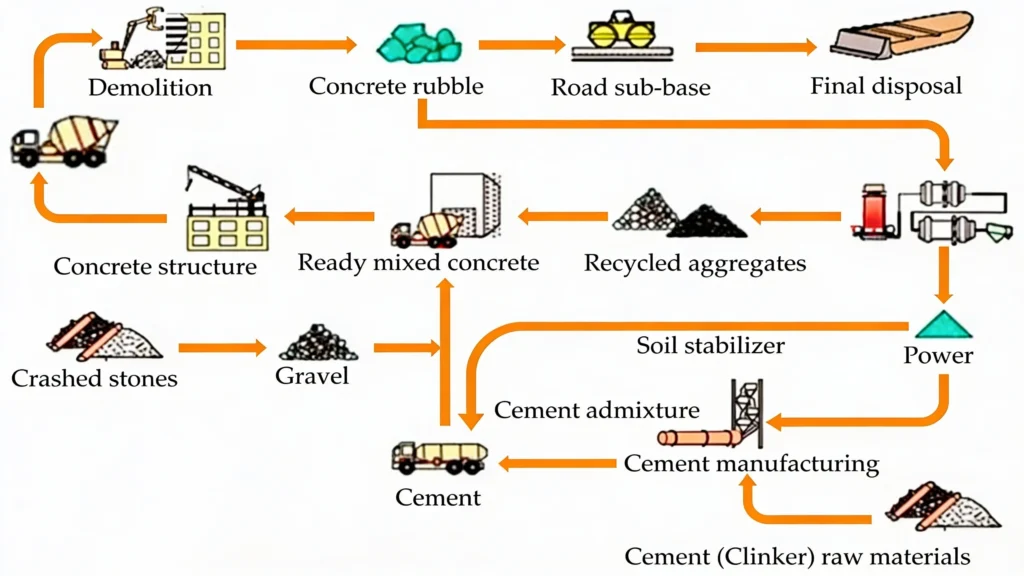

Some safety questions are now about the environment. Microplastic fibers are a real concern in the textile world. Reviews report that textiles can release fiber fragments during washing and use, and these fragments can enter water systems.

Concrete grade polypropylene fibers follow a different path. The fibers sit inside hardened concrete for most of the structure life. This lowers the chance of daily shedding in normal use. End of life still matters. Demolition and crushing can create dust that contains many kinds of particles, so dust controls and waste handling still matter.

A buyer can also look at service life. A longer lasting slab can reduce repairs, and it can reduce material use over time. This can support a practical sustainability story. Ecocretefiber™ positions fiber reinforcement as a durability tool and a risk control tool, and Shandong Jianbang Chemical Fiber Co., Ltd. supports that goal with stable quality and clear specifications.

How to Talk About Microplastics Without Fear and Without Denial

People hear “microplastics” and they often jump to a simple yes or no answer. A better way is to name the release routes and then match controls to routes. Textile studies and reviews report that washing is a major route for releasing microplastic fibers from synthetic textiles, and that these fibers can enter water systems. Other reviews also describe that fibrous microplastics can be released during manufacture and use, so the textile supply chain is one clear source. Polypropylene fibers for concrete do not follow the same daily shedding pattern because concrete locks fibers inside a cement matrix for most of the structure life. End of life still needs control because crushing and milling can create dust, and dust can move in air and water if a team does not manage it. This is why practical controls matter: a contractor uses wet cutting and local vacuum tools, and a recycler uses enclosed conveyors when possible, and a site uses good housekeeping and proper waste routing. This is a realistic sustainability story, and it fits Ecocretefiber™ because durability and sensible control steps work together.

How Ecocretefiber™ Supports Safer Use

Ecocretefiber™ is the brand of Shandong Jianbang Chemical Fiber Co., Ltd., and the product focus is concrete reinforcement fibers for professional use. Consistent fiber length and clean packaging help crews dose fibers with less mess. Clear handling notes help a buyer train crews fast. A stable supply chain helps a contractor avoid last minute substitution risk.

Practical safety support looks like this:

- The site team follows the SDS and uses ventilation and eye protection during dusty steps.

- The site team uses respiratory protection when risk assessment shows dust exposure can happen.

- The plant team controls dust and keeps good housekeeping, and this also lowers fire risk from dust build up.

Conclusão

Polypropylene fibers can be safe when teams handle them with basic dust and irritation controls, and when teams follow the SDS and local site rules. Polypropylene also sits inside major regulatory systems for plastics, and those systems show it is a well studied material when it meets the right conditions and limits. In concrete use, exposure risk often drops after curing because the cement matrix locks fibers in place, and many studies and guidance documents report that polypropylene fibers can also reduce fire spalling risk in the right design context. If you want a fiber partner that supports both performance and practical safety steps, Ecocretefiber™ from Shandong Jianbang Chemical Fiber Co., Ltd. is built for that work.