Macro synthetic fiber in one clear definition

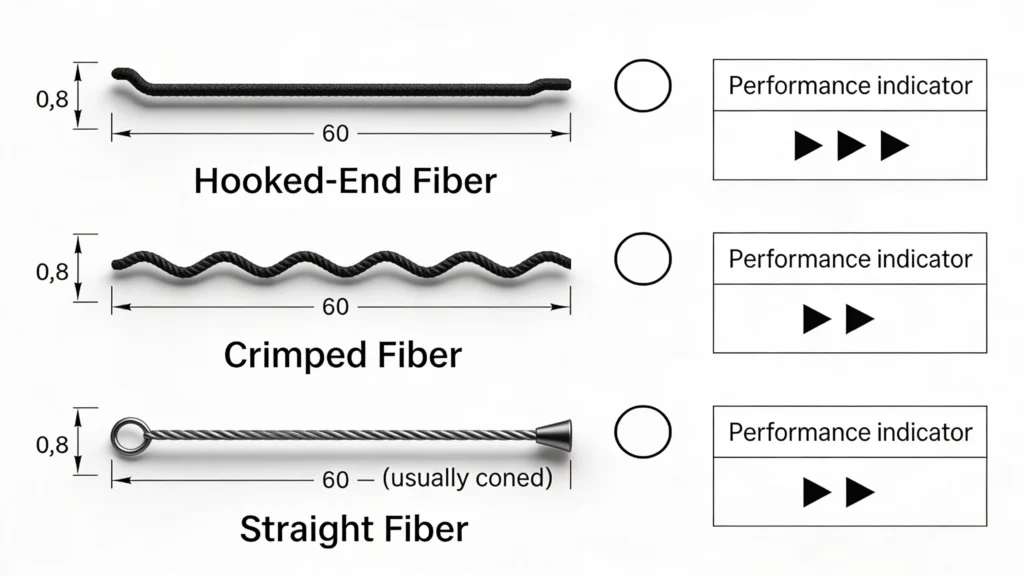

Macro synthetic fiber is a man-made fiber that a team mixes into concrete to improve crack control after cracks start. Many guides call it a “structural” synthetic fiber because it helps concrete hold load after first crack. The size is one key part of the definition. ACI guidance separates micro and macro synthetic fibers by diameter. It describes micro synthetic fibers as smaller than 0.3 mm in diameter, and it describes macro synthetic fibers as larger than 0.3 mm. The ASTM D7508 specification uses a similar cutoff through linear density, and it links that cutoff to an equivalent diameter of 0.3 mm for macro polyolefin fibers. Many macro synthetic fibers use polypropylene or other polyolefin blends, and many products use surface patterns or embossed shapes to grip the cement matrix. Industry notes also describe macro synthetic fibers as an alternative to steel fibers in some uses, especially where corrosion risk or handling issues matter.

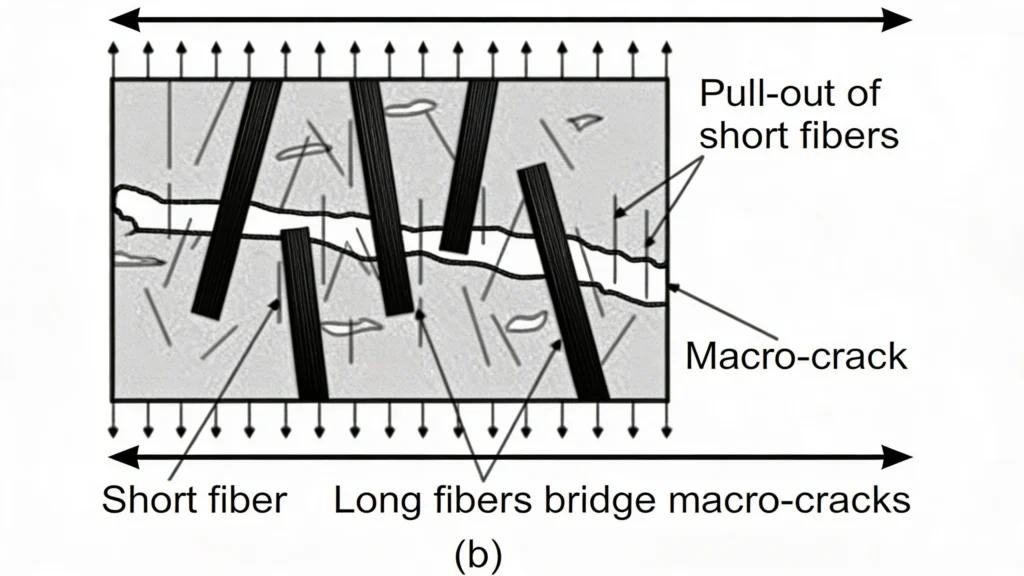

What macro synthetic fiber does inside concrete

Concrete cracks because concrete is weak in tension. A macro synthetic fiber network helps after cracks start because fibers bridge the crack faces. This bridging effect can slow crack opening, and it can raise post-crack capacity in bending and impact. Many technical sources describe macro fibers as a way to raise residual strength, toughness, and ductility in fiber reinforced concrete. Test methods focus on that post-crack part because that is where macro fibers earn their value. ASTM C1609 measures flexural performance from the load and deflection curve of a beam test, and it reports residual strengths at set deflections. EN 14651 uses a notched beam and a crack mouth opening measurement to report residual flexural tensile strengths after the first crack stage. A good buyer can ask for these test results because those numbers help a designer compare fiber options. A good buyer can also ask how the product behaves in pumping, and in finishing, and in real slab joints. A macro synthetic fiber product can look similar in a bag, but test curves often show real differences.

Macro synthetic fiber vs micro synthetic fiber

Many buyers mix up macro and micro fibers, and the mix-up causes bad specs. A micro synthetic fiber mostly helps in fresh concrete, and it helps control early plastic shrinkage cracking. A macro synthetic fiber targets performance after cracking, so it supports post-crack load and crack width control. ACI guidance uses the 0.3 mm size line to separate micro and macro. ASTM D7508 also sets the macro and micro split through denier and equivalent diameter. Some industry bulletins also point out that ASTM C1116 Type III covers synthetic fibers and it can include micro and macro fibers, so a spec should not rely on “Type III” alone. A project team should name what the fiber must do. A project team should name the target test method and target residual strength, or the project team should name the use case like slab reinforcement or shotcrete reinforcement. A project team can use both fiber types together in some mixes, but each fiber type needs its own job in the design.

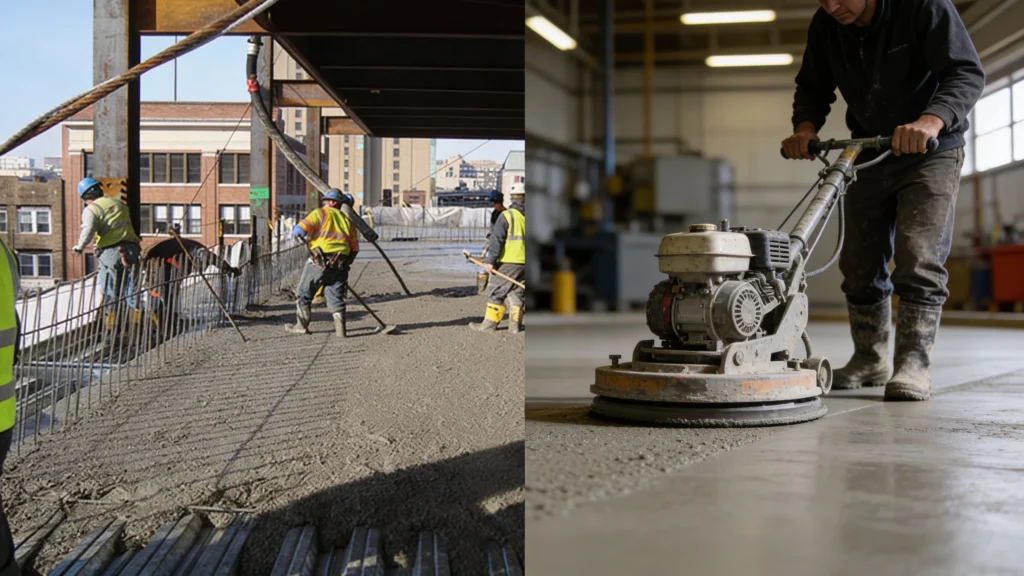

Where macro synthetic fiber is used most

Macro synthetic fiber fits best where cracks and impact and fatigue matter, and where a crew wants a faster workflow than welded wire mesh. Many slab-on-ground projects use macrofibra sintética to help with crack control and to support post-crack capacity in areas like warehouses, yards, and logistics floors. Some sprayed concrete and mining shotcrete work also uses macro synthetic fibers, and some guides describe these fibers as a steel-fiber alternative in parts of sprayed concrete practice. Some public agencies also discuss macro and micro fibers as common polymeric options in concrete work, which shows that fiber use is mainstream, not niche. Precast producers also use macro fibers in selected products where toughness and edge durability matter, and where steel placement is hard. Pavements and overlays also use macro fibers in some designs because repeated wheel loads open small cracks over time. A buyer should still treat each use case as a design problem, not as a simple “add fibers” step.

How engineers and spec writers usually specify it

A good specification names performance and durability and compliance. ASTM C1116 defines Type III synthetic fiber reinforced concrete and it requires documentary evidence that the fibers resist deterioration in the concrete environment and with common admixtures. Many macro synthetic fiber products also claim compliance with ASTM C1116 Type III, and that claim is common on major product pages. In Europe and many export markets, EN 14889-2 sets definitions and requirements for polymer fibers for concrete, and it supports conformity rules for that product type. A designer often needs performance data, so the designer often uses test methods like ASTM C1609 or EN 14651 to set minimum residual strength values at set crack openings or deflections. Some national guides also list what properties a buyer should include for macro synthetic fibers, such as fiber class, length, equivalent diameter, tensile strength, and effect on workability at dosage. A buyer should ask for test reports from an accredited lab, and the buyer should ask for mix notes, and the buyer should ask for dosing guidance that matches local aggregates and cement.

Mixing and finishing basics that matter on site

A macro synthetic fiber needs good dispersion. A crew should add fibers in a controlled way, and the crew should avoid dumping one full bag into one small spot. A crew should also keep mixing time long enough for the fiber to spread through the mix. Some guides note that macro synthetic fibers can change mix consistency, so a crew should plan slump and admixture use around the chosen dosage. A finishing crew should also expect some fiber visibility at the surface in some mixes, and the crew should tune finishing timing and tools to reduce that issue. A ready-mix producer should confirm pumpability because long fibers can affect line flow in some conditions. A spec should keep these jobsite effects in mind because a fiber that looks great in test beams still needs smooth placement in real slabs.

What macro synthetic fiber can replace, and what it should not replace

Some marketing claims say macro synthetic fibers replace mesh or rebar. Some projects do use macro fibers as a replacement for welded wire mesh in selected slab designs, and some fiber guidance pages describe that use. A buyer still needs engineering review because each slab has joint spacing, subbase stiffness, load type, and crack risk. A buyer should also keep in mind that bars still handle concentrated forces and controlled crack design in many structural members. A macro synthetic fiber works best as distributed reinforcement, and it works best where designers value post-crack behavior. Some DOT and research reports also review macro synthetic fibers in structural contexts and they treat the topic as engineering, not as a simple swap. A responsible supplier should support the buyer with test data and design references, and the supplier should avoid one-size-fits-all claims.

Why buyers choose Ecocretefiber™

A buyer usually wants three things. A buyer wants stable fiber geometry. A buyer wants clear compliance documents. A buyer wants performance data that matches common test methods. Ecocretefiber™ is a brand of Shandong Jianbang Chemical Fiber Co., Ltd., and the product focus is concrete reinforcement fibers for professional projects. Our team supports product selection with clear specifications, and our team supports performance-based discussions with test data targets that match common standards used for fiber reinforced concrete. Our supply approach also supports repeatability, which helps ready-mix plants keep mix behavior stable from batch to batch.

Conclusão

Macro synthetic fiber is a structural synthetic fiber that a team mixes into concrete to improve post-crack performance. A common definition uses the 0.3 mm size line, and ASTM D7508 links that line to macro polyolefin fiber classes. Macro synthetic fibers help by bridging cracks, and tests like ASTM C1609 and EN 14651 help buyers and designers measure residual strength and toughness. A good specification names compliance and durability and performance targets, and standards like ASTM C1116 and EN 14889-2 support that approach. If you want a supplier that supports performance-based buying and steady delivery for real concrete production, Ecocretefiber™ from Shandong Jianbang Chemical Fiber Co., Ltd. is ready to support your next mix design.