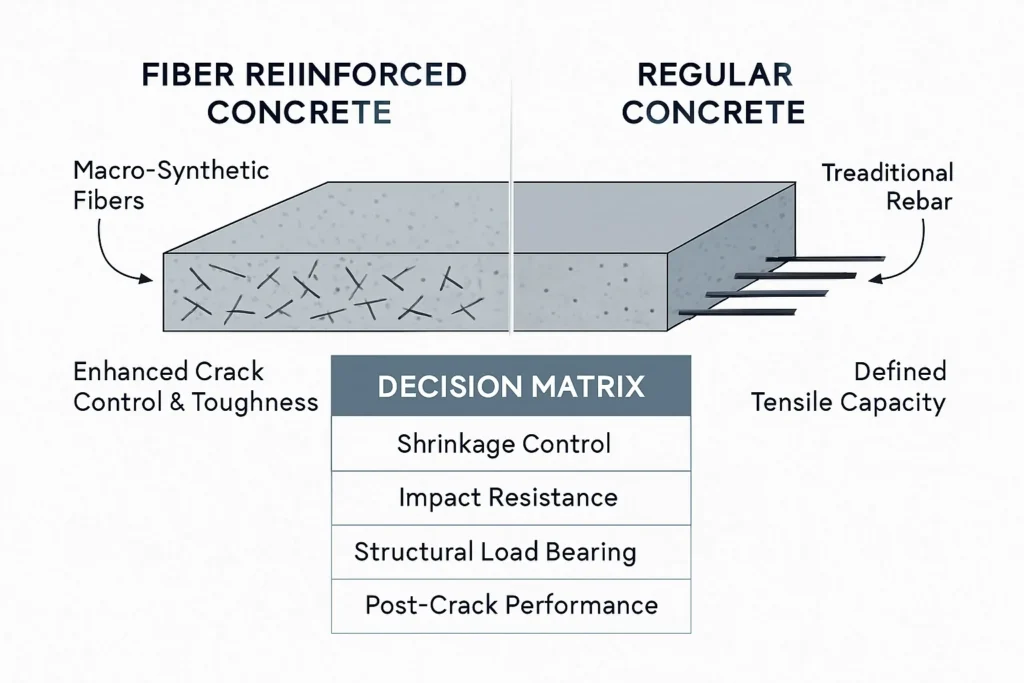

Fiber concrete can be better than regular concrete, but only when it solves the problem you actually have. Fiber concrete often gives better crack control. It can improve toughness after cracking. It can reduce impact damage in floors and pavements. Synthetic fibers are also widely used to reduce plastic and drying shrinkage cracking. They can increase energy absorption and impact resistance.

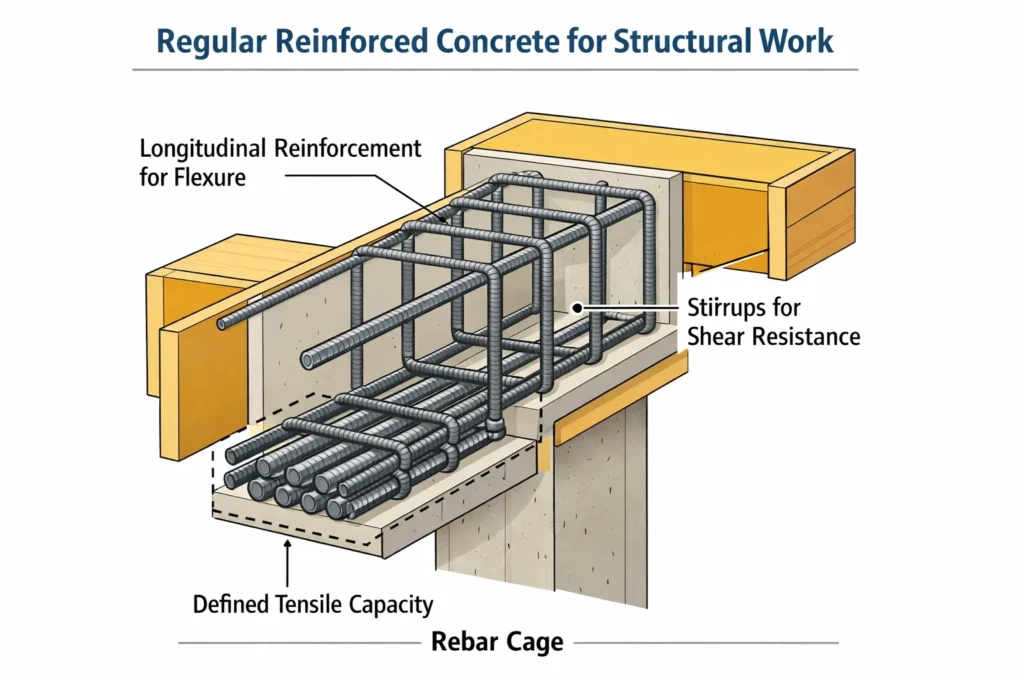

Regular concrete is still the best choice for many structural elements when the design depends on rebar in defined tension zones. In many beams, columns, walls, and elevated slabs, a conservative approach is to design reinforcing bars to carry the full tensile loads. Fibers can supplement and sometimes reduce steel, but they do not automatically replace it.

So the right answer is not “always.” The right answer is “it depends on the goal, the loads, the exposure, and the spec.”

What is fiber concrete, what is regular concrete?

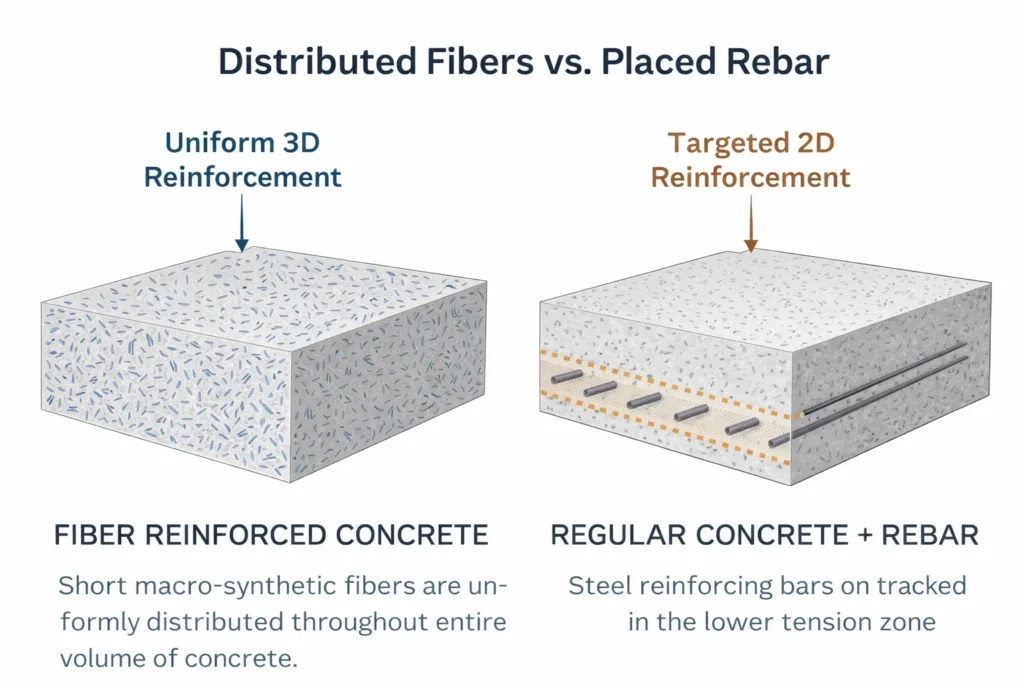

Fiber concrete is concrete that contains short fibers mixed throughout the batch. The fibers are uniformly mixed at delivery. That is also how standards define fiber-reinforced concrete for supply and testing at the point of delivery.

Regular concrete is the standard mix used on most sites. It may be plain concrete, or reinforced with rebar or welded wire fabric. It usually does not include fibers unless the mix is specified as fiber reinforced.

A simple way to see the difference on site is this:

- Regular concrete + rebar: steel is placed in specific locations before the pour.

- Fiber concrete: fibers are already in the mix. Reinforcement exists across the full volume.

Fibers are not all the same. Some are meant for early-age crack control. Some are meant for post-crack toughness. That choice decides whether fiber concrete is “better” for your job.

When fiber concrete is better

Fiber concrete is often better when the project is driven by cracking risk, surface durability, or impact performance.

Better crack control in early hours

Plastic shrinkage cracks can form fast when evaporation is high. Industry guidance notes that synthetic fibers help reduce plastic and drying shrinkage crack formation.

NRMCA guidance on plastic shrinkage cracking also suggests considering synthetic fibers (ASTM C1116) to help minimize plastic shrinkage cracking.

Bessere Zähigkeit und Schlagzähigkeit

Many fiber systems increase energy absorption and improve resistance to impact forces.

This matters in warehouse floors, hardstands, pavements, and loading zones where repeated traffic causes joint distress and corner breaks.

Better service life in harsh exposure

Durability is not only “strength.” It is also crack width and fluid entry. A widely stated benefit of fiber-reinforced concrete is tight crack control, which helps reduce crack width and helps prevent water and aggressive solutions from penetrating deeper into the concrete.

That is valuable in freeze-thaw regions, de-icing salt exposure, and wet industrial environments.

Better construction flow in some slabs

For some slab-on-ground designs, fibers can reduce the need for handling welded mesh on site. This can reduce labor, improve schedule reliability, and reduce trip hazards. This benefit depends on design method and fiber type, not on microfibers alone.

When regular concrete is better

Regular concrete can be the better choice when the project needs defined structural capacity, simple supply, or the lowest upfront cost.

Structural tension still needs steel in many members

In many structural members, a conservative approach is to design reinforcing bars to carry the total tensile loads. That guidance is stated in ACI’s design-oriented discussion of fiber use in structural members.

That is why regular reinforced concrete remains the default for beams, columns, suspended slabs, and many walls.

Lower cost and simpler batching

Fiber adds cost per cubic meter. Some fibers also change workability. Microfibers are usually easy. Macro fibers and steel fibers can require more control. If the project does not have a crack-driven need, fiber spend can be waste.

Easier finishing for certain surface specs

Many slabs finish well with fibers, but some surface specs are strict. Macro fibers can increase the chance of visible fiber at the surface if finishing timing is poor. If the slab will be polished, stained, or exposed architectural concrete, the contractor may prefer regular concrete plus controlled reinforcement, then manage cracks by jointing and curing.

Simpler inspection and code pathway

Many jurisdictions have clear workflows for regular reinforced concrete. Fiber structural design is possible, but it depends on accepted methods, test data, and engineer comfort. This is not a problem, but it is a reality in bidding and approvals.

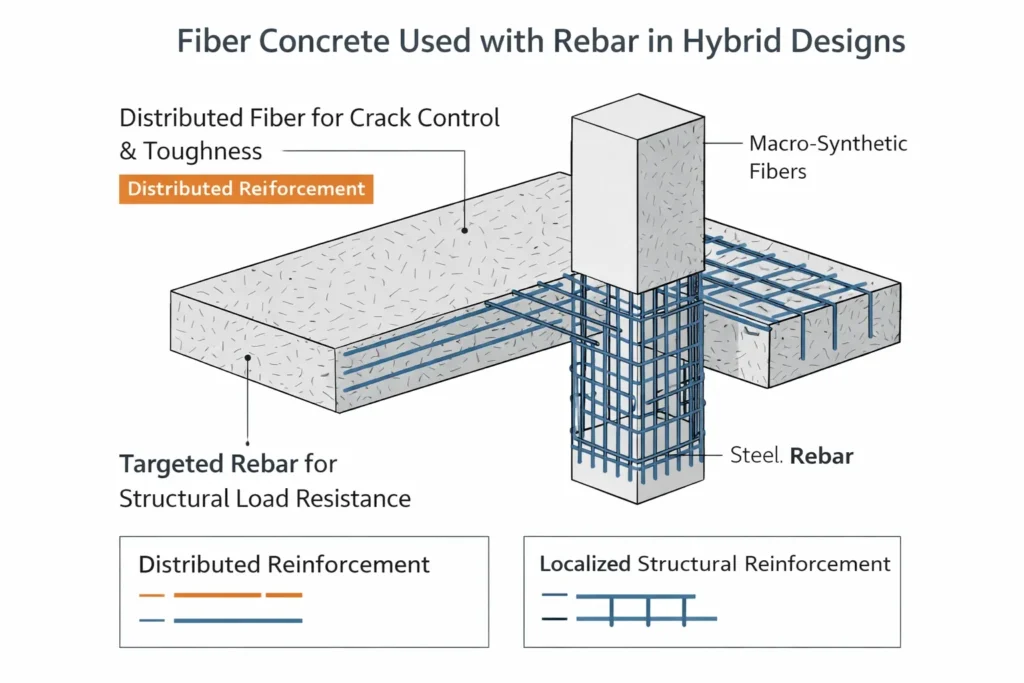

Does fiber concrete replace rebar?

For most structural projects, the answer is “no.” Fibers and rebar do different jobs.

A clear way to state it is this:

- Rebar is continuous steel placed where tension is expected.

- Fibers are discontinuous reinforcement distributed throughout the mix.

ACI’s design guide preview states that in many structural members, reinforcing bars should be used to support the total tensile loads. It also notes fibers can supplement and reduce reinforcement in some cases.

Also, micro fibers are not structural reinforcement in the normal sense. Industry guidance states micro fibers are not a structural reinforcing fiber and cannot be used to replace structural steel elements, with a limited slab-on-ground mesh exception in specific cases.

So fiber concrete can replace or reduce some steel in certain slabs-on-ground or specific engineered systems. It does not remove the need for rebar in most beams, columns, and suspended structural slabs.

What are the downsides of fiber concrete?

Fiber concrete has real benefits. It also has real constraints. These constraints are usually execution issues, not “fiber is bad.”

Wrong fiber choice

Micro fibers mainly help early shrinkage cracks. They do not provide meaningful post-crack load capacity for heavy-duty slabs. Macro fibers are a different category.

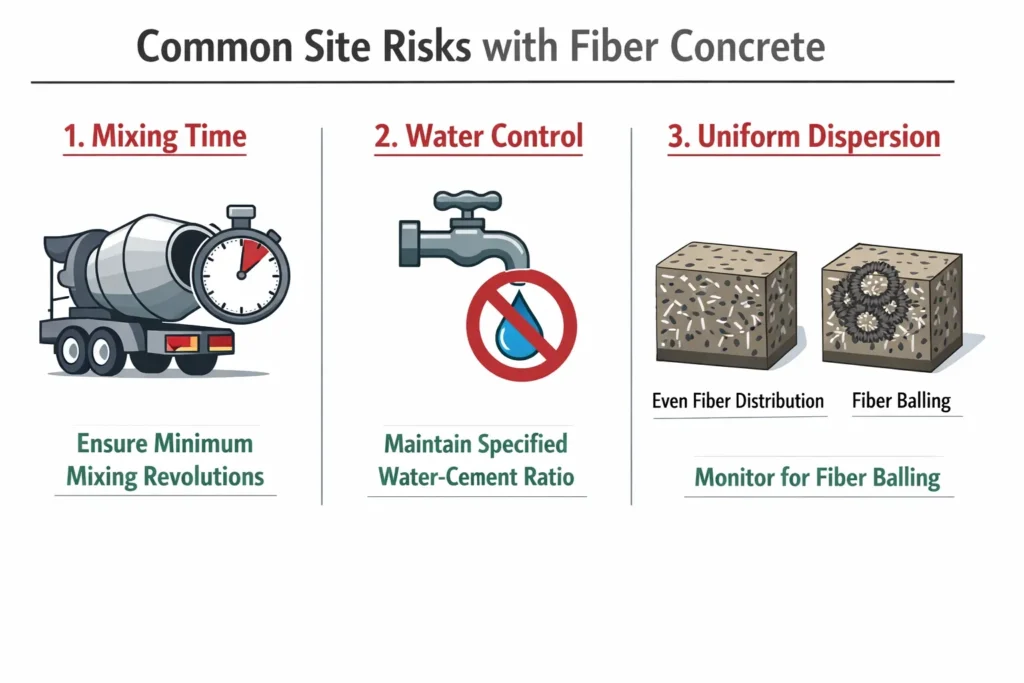

Poor mixing can reduce performance

Fibers must be uniformly dispersed. ASTM C1116 focuses on fiber-reinforced concrete delivered with ingredients uniformly mixed, but placement and curing are still on the contractor.

If fibers clump, performance drops.

Workability and finishing changes

Higher fiber dosages can reduce slump feel. That can trigger bad site habits like adding water. Water addition raises cracking risk, so it defeats the purpose.

False confidence

Fibers reduce cracking risk, but they do not fix poor curing. They do not fix weak subgrade. They do not fix a bad joint plan.

NRMCA’s guidance on synthetic fibers states fibers reduce plastic and drying shrinkage cracking and increase impact resistance, but this should be treated as part of a full quality plan, not a replacement for good practices.

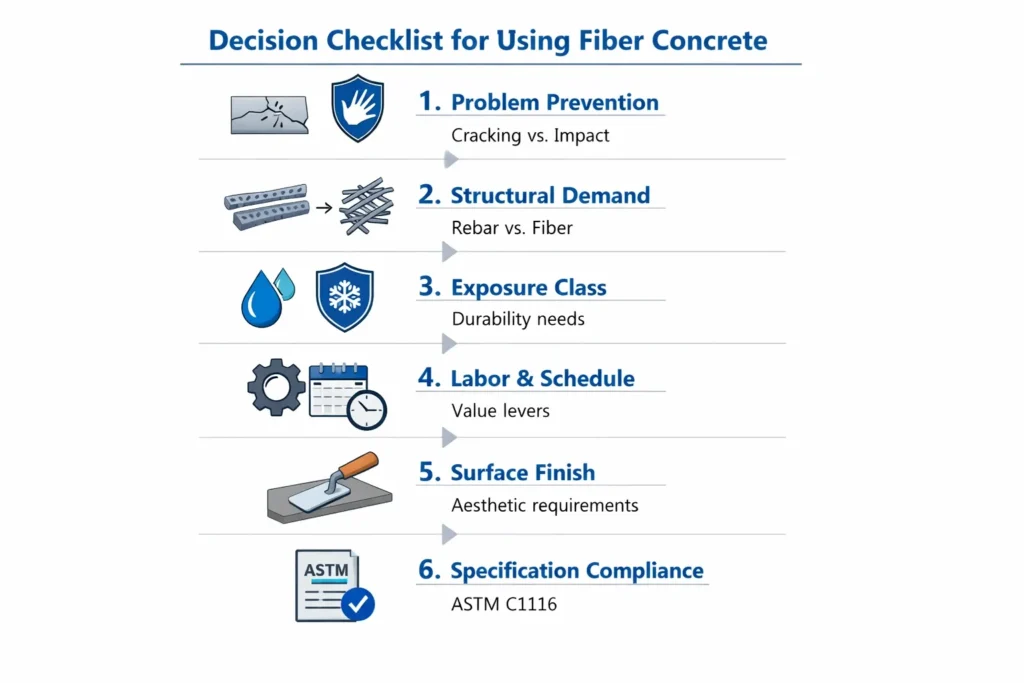

How to decide: a practical checklist

If you want a simple decision path, use this checklist. It keeps the conversation grounded.

- What is the main problem you want to prevent?

- Plastic shrinkage cracks: micro synthetic fiber is often a good fit.

- Joint damage and impact: macro synthetic or steel fiber is more relevant.

- Is the element structural or non-structural?

- Structural beams, columns, suspended slabs: plan on rebar first.

- Slabs-on-ground and pavements: fiber can be very effective.

- What is the exposure class? If water, salt, chemicals, or freeze-thaw are key risks, tighter crack control improves durability performance claims in many industry discussions.

- What is your labor situation? If mesh placement is costly or hard to schedule, fiber can be a strong value lever.

- What is the surface requirement? If you need a perfect exposed finish, plan a trial panel with the chosen fiber and finish method.

- What does the spec allow? ASTM C1116 is the standard specification that defines the fiber-reinforced concrete product delivered to a purchaser. It helps with consistency and acceptance language.

If you can answer these items, the decision becomes straightforward. Many projects end up choosing a hybrid: rebar where required, fiber for crack control and toughness.

Ecocretefiber™ guidance: getting the benefits without the risk

Fiber concrete performs best when selection and execution are controlled. That means fiber type, dosage, mixing method, curing plan, and the right expectation about rebar.

Ecocretefiber™ ist die Fasermarke von Shandong Jianbang Chemical Fiber Co., Ltd. We support customers with general guidance first, then product matching:

- Micro fiber options for plastic shrinkage crack control

- Macro synthetic fiber options for slab toughness and post-crack performance goals

- Mixing guidance to reduce clumping risk

- Dosage suggestions based on application goals, then verified by trial pours

- Documentation support aligned with common specification language such as ASTM C1116 where relevant

If you are a distributor, we also support cooperation with stable supply and consistent documentation.

Schlussfolgerung

Fiber concrete is better than regular concrete when the job is driven by crack control, toughness, impact resistance, or durability in harsh exposure. Synthetic fibers are specifically described as helping reduce plastic and drying shrinkage cracking, while increasing energy absorption and impact resistance.

Regular reinforced concrete is better when the design depends on clear tensile capacity in specific locations, especially in structural members where reinforcing bars are expected to carry tensile loads.

If you want the best result, define the goal first. Then choose the fiber type that matches that goal. Keep rebar where the structure needs it.