Traditional concrete is strong but heavy. It cracks easily in thin sections. That limits design, slows installation, and eats profit.

Glass fiber reinforced concrete (GFRC) offers a different route. It mixes alkali-resistant glass fibers into a fine, cement-rich matrix. The result is a thin concrete skin with high strength, low weight, and good crack control. This makes GFRC very attractive for facades, countertops, furniture, and many decorative elements where both appearance and performance matter.

What Is Glass Fiber Reinforced Concrete (GFRC)?

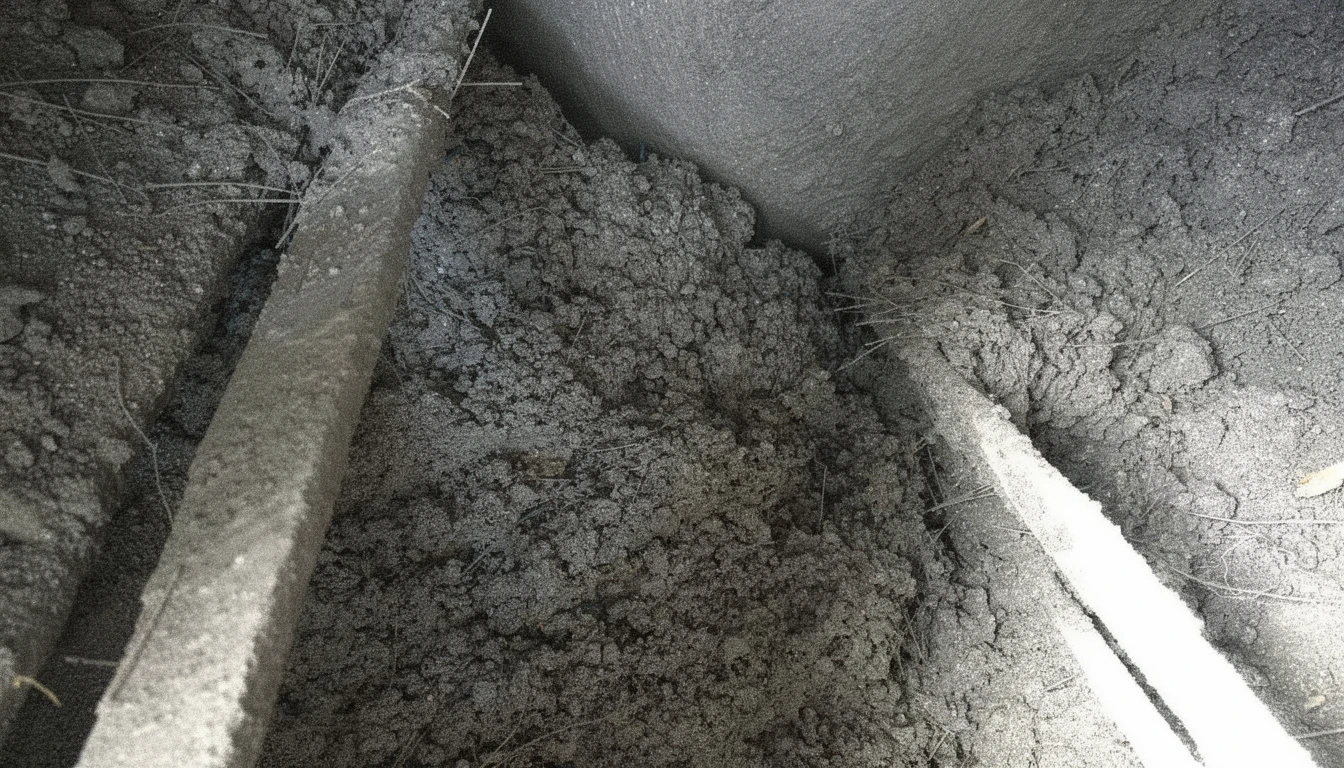

GFRC is a type of fiber-reinforced concrete that uses countless alkali-resistant glass fibers instead of steel bars or steel mesh. These fibers sit inside a mortar made from cement, fine sand, water, polymers, and admixtures. The mix has no coarse aggregate. This gives a dense, strong skin rather than a thick block.

Producers cast GFRC into molds for facade panels, cladding pieces, planters, benches, worktops, sinks, and many custom shapes. It suits projects that need thin sections, sharp details, and a smooth finish, while still keeping good strength and durability.

Concrete is strong in compression but relatively weak in tension. In standard mixes, the first micro cracks appear early. They can grow into visible lines that spoil the surface. In glass fiber reinforced concrete, thousands of small glass filaments sit inside every part of the section. Each filament works like a short anchor that grips the cement paste. When a load tries to bend or pull the concrete, the matrix starts to crack, but the fibers hold the two sides together. The stress spreads across many fibers instead of one single crack line. Crack widths stay very small, so water and dirt have fewer paths into the concrete. This higher flexural and tensile capacity means a thin GFRC panel can carry loads that would demand a much thicker traditional slab. For visible elements such as countertops, feature walls, or facade panels, this strength turns into real value, because you can offer slim, elegant pieces that still feel safe and solid to the customer.

Benefit 1: Higher Strength And Better Crack Control

Owners worry about hairline cracks, chips, and early damage in visible concrete. Once a customer sees cracks, trust drops, even if the structure is still safe.

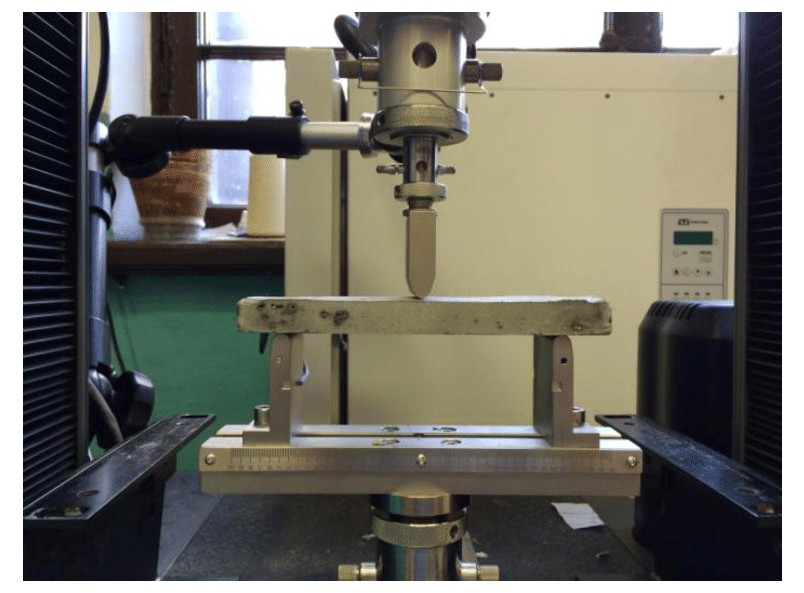

GFRC gives much higher flexural and tensile strength than plain concrete of the same thickness. The glass fibers bridge micro cracks and help keep them tight. This improves performance during transport, installation, and long-term use.

In plain concrete, once a crack starts, there is little to stop it from opening. The stress focuses at the crack tip. The section loses stiffness very quickly. GFRC behaves in a more forgiving way. When bending forces act on a GFRC panel, many micro cracks appear instead of one big crack. Glass fibers cross each of these fine cracks. They pick up tensile forces and share them across the whole cross section. The panel can deflect more before failure, so it shows warning rather than sudden breakage. At service loads, most cracks stay tight enough that you cannot see them from a normal viewing distance. This is very important for exposed work such as reception counters or building facades, where appearance sells the product. With Ecocretefiber™ alkali-resistant glass fibers, you get consistent filament quality and controlled fiber content, so this crack control effect is stable from batch to batch.

Benefit 2: Much Lower Weight For Easier Handling

Heavy pieces slow a project. They need large cranes, strong fixings, and more people on site. Every lift carries risk.

GFRC elements can be very thin. A typical GFRC panel or countertop is often half the thickness of a traditional reinforced piece, sometimes even less. Lower thickness means lower volume, so total weight drops sharply. This makes handling, shipping, and installation much easier.

Think of a solid concrete countertop at 50 mm thickness. Now imagine the same plan size in GFRC at 20 mm thickness with ribs on the underside. The second piece uses far less material. The weight per square meter can fall by 50–75% depending on the exact design. This change brings several practical gains. Workers can carry many pieces without heavy equipment, which speeds up small jobs and interior fit-out. Transport costs drop because you place more units in one container or on one truck. On site, lighter cladding often needs a simpler subframe. In some projects, you can even reduce the size of structural steel or anchors, because the facade load is lower. For landscape products, lighter benches and planters are easier to reposition. In every case, the client still sees “real concrete,” but your team knows the elements are much easier to move. Ecocretefiber™ glass fibers help you keep this thin yet strong design consistent, so you can standardise production and marketing.

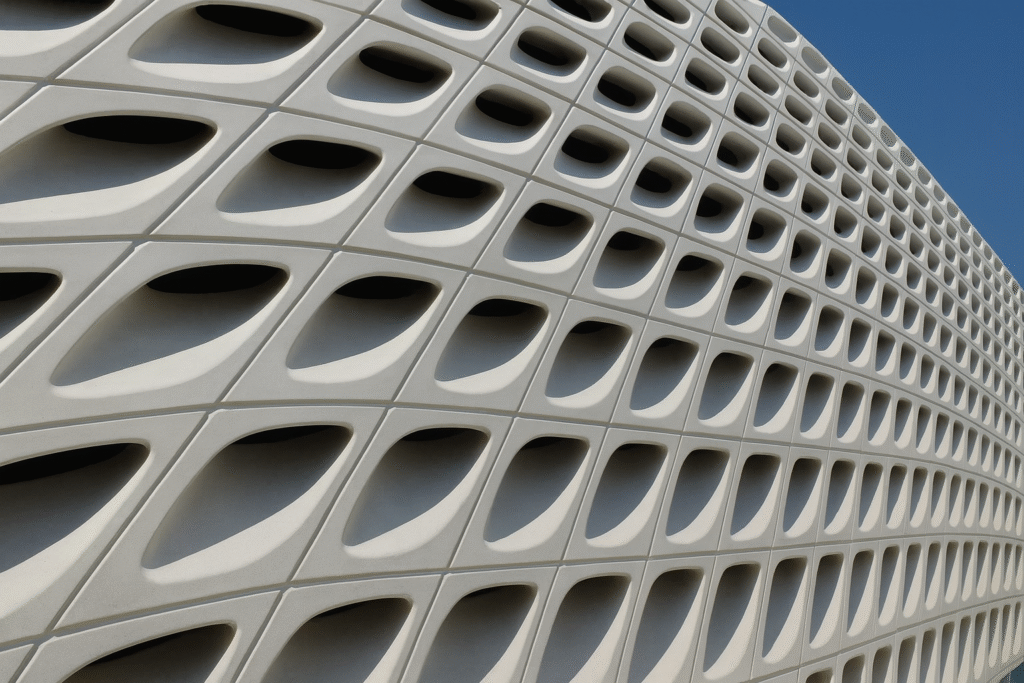

Benefit 3: More Design Freedom With Thin And Complex Shapes

Architects like bold lines, long spans, and fine details. Traditional concrete forces them to keep sections thick. That hides texture and breaks up surfaces with joints.

GFRC opens more options. It flows into detailed molds and cures into thin shells with stiffening ribs. You can create curves, folds, and perforations that would be hard or risky with normal reinforced concrete.

A GFRC mix uses fine sand and no coarse stone. This gives good mold filling in tight corners, around letters, or along deep textures. Polymer modification improves bond and toughness. The glass fibers sit in this compact matrix and support delicate forms once the piece cures. You can design hollow panels with hidden ribs rather than solid slabs. That keeps the front face slim while the ribs control deflection. Long counters can span between fewer supports, so the visual field looks clean and continuous. Facade designers can cut deep grooves, cast sharp arrises, or add integrated returns without a heavy edge build-up. GFRC also takes pigments and surface treatments well, so you can mimic stone, create strong brand colors, or keep a raw concrete look. By using Ecocretefiber™ fibers in a proven GFRC recipe, you turn these design ideas into repeatable products instead of one-off experiments.

Benefit 4: Improved Durability In Real Conditions

Outdoor concrete must cope with rain, temperature swings, and pollution. Indoor elements face spills, cleaning agents, and daily wear. If the material fails early, you lose money on repairs and replacements.

GFRC has good durability for these conditions. Alkali-resistant glass fibers do not rust like steel. Tight crack patterns reduce the pathways for water and aggressive agents. Thin sections dry faster after wet periods, which also helps.

In a standard reinforced concrete panel, corrosion often starts at the steel. Water and salts reach the bar through pores or visible cracks. As rust forms, it expands. That expansion pushes on the surrounding concrete until the cover spalls. GFRC removes this major weak point. The main reinforcement is glass fiber with a special coating that resists the alkaline concrete environment. There is no steel bar that can rust. The fibers are distributed through the whole cross section, so even if small cracks form, they stay narrow. Narrow cracks slow down water ingress. In many climates this makes the difference between minor aging and serious damage. For countertops, sinks, and furniture, the dense matrix plus polymer modification gives a surface that holds up well under normal use. Proper sealing adds another layer of safety. When you combine these material traits with stable Ecocretefiber™ AR glass fibers, you get elements that continue to look good for years after installation, which is exactly what repeat customers remember.

Benefit 5: Lower Total Project Cost And Faster Installation

Material price is only one part of cost. Labour, time, and risk on site matter more in many projects.

GFRC can cut total cost by saving time and effort in production, transport, and installation. Thinner, lighter elements move through each step with less trouble. Less damage and fewer callbacks also protect margin.

A GFRC system fits well with off-site construction. You cast panels or furniture in a controlled plant. Molds, vibration, curing, and demolding all follow a stable process. That reduces waste and rework. Once cured and sealed, the elements travel to site as finished goods. Site crews only need to fix them in place. There is little or no on-site concreting for these parts, so weather causes fewer delays. Lighter units make lifting simpler. In many cases, a small mobile crane or even manual handling is enough. This shortens crane time and reduces congestion on busy city projects. Because GFRC panels show fewer cracks and chips, you avoid many small repairs before handover. That frees your team to move on to the next job. For precast producers and decorative concrete studios, this efficiency means more output from the same equipment. With Ecocretefiber™ as a long-term glass fiber supplier, you can plan production, stock, and pricing with confidence, instead of adjusting to quality swings from unknown sources.

Conclusion

Glass fiber reinforced concrete turns heavy, crack-prone concrete into a thin, strong, and attractive skin. Higher strength with good crack control improves performance in service. Low weight speeds transport and installation. Thin, complex shapes create a clear visual advantage in the market. Better durability reduces complaints. Lower total project cost helps you win jobs without cutting profit to the bone. When you build your GFRC mixes around reliable Ecocretefiber™ glass fibers, these five benefits become a repeatable part of your business model, not just a promise on paper.

Ecocretefiber – Your Partner For GFRC Projects

Ecocretefiber™ is the fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. We supply alkali-resistant glass fibers designed for GFRC, together with other advanced fibers for concrete and mortar. Our products focus on stable strength, consistent sizing, and good dispersibility in the mixer. That gives you predictable behaviour in spraying or casting. We support precast producers, decorative concrete shops, and building material distributors with technical suggestions on mix design and dosage, plus marketing content that helps you explain the value of GFRC to your own clients. If you plan to grow your GFRC product line, Ecocretefiber™ is ready to work with you as a long-term, reliable fiber partner.