Cracks in slabs and screeds hurt every project. They create complaints, extra labour, and hidden cost.

Polypropylene fiber for concrete is a small addition to the mix that helps keep those cracks under control. It improves surface quality, supports durability, and protects your margin with very low cost per cubic meter.

What Is Polypropylene Fiber for Concrete?

Polypropylene fiber is a synthetic fiber made from polypropylene. It has low density, good chemical resistance, and no rust risk. The material stays stable in the alkaline concrete pore solution.

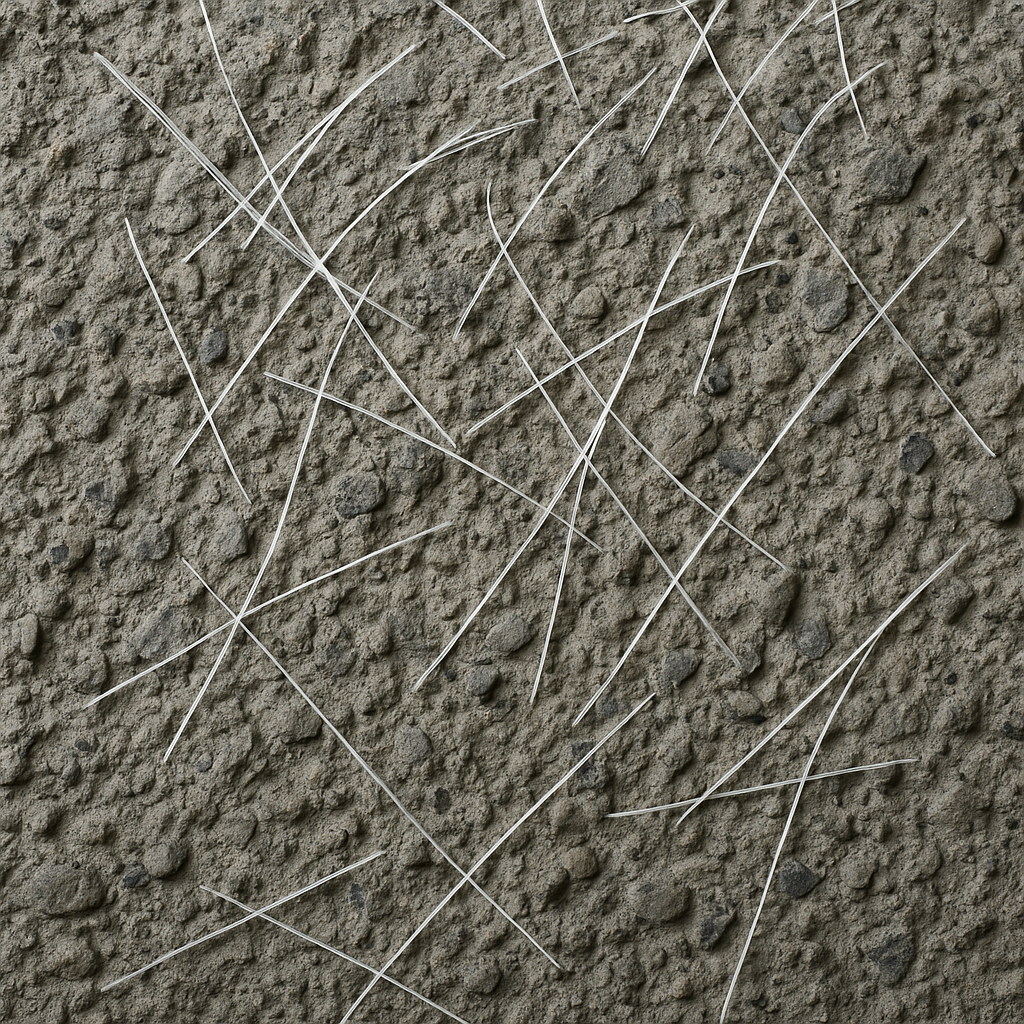

For concrete use, the fiber comes in different forms:

- Fine monofilament micro fibers

- Fibrillated micro fibers that open into a mesh

- Larger macro fibers with higher stiffness

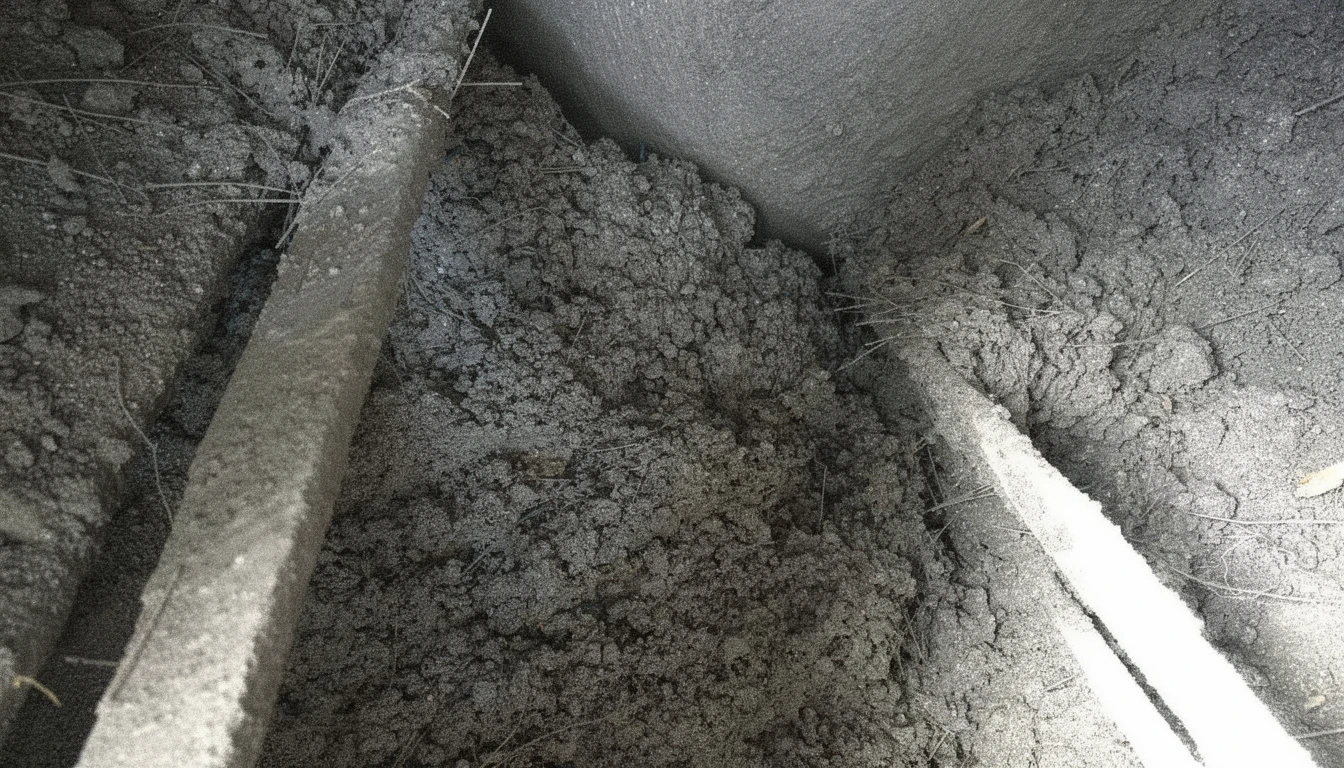

You dose the fibers straight into the mixer. The strands spread through the paste and create a three-dimensional network inside the concrete. No change to basic batching equipment. No special tools for site crews.

Ecocretefiber™ polypropylene fibers from Shandong Jianbang Chemical Fiber Co., Ltd. are produced with tight control of diameter, length, and cutting quality. This helps the fibers disperse quickly and keeps performance stable from batch to batch.

How Polypropylene Fiber Works in Fresh and Hardened Concrete

The main weakness of concrete is tension. In the first hours, the surface shrinks while the deeper concrete stays wet. Later, traffic, temperature change, and load cycles create new micro cracks.

Polypropylene fiber for concrete targets both stages.

In fresh concrete, micro fibers sit between cement grains and fine sand. They help stabilise the solid skeleton. Bleed water channels become less continuous. Bleeding drops in rate and volume. The surface stays more uniform. When evaporation is high, fibers also limit plastic shrinkage cracking. Cracks still try to form, but they stay shorter and much finer. In many slabs you cannot see them without close inspection.

In hardened concrete, macro polypropylene fibers bridge micro cracks that form under load. The fibers cross the crack plane and carry part of the tensile stress. The crack still exists, but it opens more slowly. The section keeps more stiffness after first cracking. The concrete shows a tougher load–deflection curve instead of brittle break. For industrial floors and pavements this behaviour means better joint performance, fewer random cracks, and a longer service life.

Main Benefits of Polypropylene Fiber in Concrete

Polypropylene fiber for concrete is popular because it solves very common problems with a simple step.

Key benefits include:

- Reduced plastic shrinkage cracking in slabs and screeds

- Better surface quality with less crazing and dusting

- Higher impact and abrasion resistance in many mixes

- Lower permeability due to a tighter crack pattern

- No rust, no staining from corrosion at the surface

For many projects, the first visible result is a cleaner top layer. Fewer plastic shrinkage cracks. Less settlement over rebar or joints. Fewer repairs before handover. Over time, tighter cracks and lower permeability slow down damage from water, salts, and freeze–thaw cycles. That means fewer callbacks and lower lifecycle cost for the owner.

Dosage and Mix Tips for Polypropylene Fiber

Guessing at dosage wastes money. Too little fiber does almost nothing. Too much can make finishing harder.

For micro polypropylene fiber for concrete, a common range is:

- 0.6–1.0 kg per m³ as a starting point for slabs, screeds, and precast surfaces

At these levels the mix stays workable with a small adjustment to admixtures. The fibers create a dense network in the top layer and reduce early cracking.

For macro polypropylene fibers, typical dosages are higher:

- 2–6 kg per m³ for structural use in industrial floors and pavements, based on design

Higher dosages need proper mix design. You may increase paste volume slightly. You almost always use a superplasticizer to keep slump in the target zone. Trial mixes are essential. Check workability, finishing, and test beams or cubes.

When you work with Ecocretefiber™, the technical team can suggest dosage bands for each product and project type. That shortens your test phase and helps you reach a mix that crews accept on site.

Typical Applications of Polypropylene Fiber for Concrete

Polypropylene fiber fits many standard products. It is not only for “special” jobs.

Common applications include:

- Ground-supported industrial floors in warehouses and factories

- Screeds and toppings in commercial and residential projects

- Precast rings, channels, covers, and small panels

- Roads, hardstand areas, and external pavements

- Shotcrete for lining and repair

- Bagged repair mortars, renders, and dry-mix products

In floors, micro fibers support the surface during finishing. The top zone becomes more uniform. Dusting and flaking drop. In screeds, fiber helps limit random cracking from restraint and drying. For precast units, fiber improves impact resistance during demolding, storage, and transport. Dry-mix producers use polypropylene fibers to improve cohesion and reduce sag or shrinkage cracking on vertical repairs.

Can Polypropylene Fiber Replace Steel Mesh?

This question comes up in many meetings. The short answer is simple.

Micro polypropylene fiber for concrete does not replace structural rebar. Its job is to control early cracking and improve surface performance.

Macro polypropylene fibers can replace temperature and shrinkage mesh in some ground-supported slabs and pavements. This only works when there is a proper design method, a tested fiber product, and the correct dosage. For beams, columns, suspended slabs, or key structural elements, conventional reinforcement still carries the main tensile forces.

A practical approach is to use:

- Micro fibers for crack control and durability

- Macro fibers for toughness and mesh replacement in selected slabs

- Rebar where you need defined structural capacity

Ecocretefiber™ can support your engineer with data sheets and design guidance, so any replacement of mesh is based on numbers, not wishful thinking.

Conclusion

Polypropylene fiber for concrete is a small change in the mix with a big effect on performance. It cuts plastic shrinkage cracking, helps the surface last longer, and supports durability under real site conditions. Macro versions add toughness and keep cracks tight under load. The fibers do not rust, they are light, and they fit smoothly into existing batching routines.

For ready-mix plants, precast factories, and dry-mix brands, this is a simple upgrade. You add clear value without slowing production. With reliable supply from Ecocretefiber™ and good technical support, polypropylene fiber becomes a quiet but important part of your product strategy.

Ecocretefiber – Polypropylene Fiber Supplier from China

Ecocretefiber™ is the concrete fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. We produce polypropylene fibers for concrete in micro and macro grades. Our products cover slabs, screeds, precast elements, pavements, shotcrete, and dry-mix systems.

Each batch focuses on:

- Stable length and diameter

- Clean cutting with low fuzz

- Good dispersion in standard mixers

We also provide dosage tables, mix suggestions, and marketing content in English. This helps you explain the value of polypropylene fiber for concrete to your own customers. If you want to add or upgrade fiber solutions in your range, our team is ready for long-term cooperation.