Polypropylene fiber is a synthetic fiber made from polypropylene resin. It is lightweight, stable, and non-corrosive. It is widely used in concrete, mortar, plaster, and many cement-based products to improve crack control and surface durability.

This article explains what a polypropylene fiber is, how it works in cement mixes, where it is used, and what you should watch out for when choosing dosage or suppliers.

What is a polypropylene fiber?

Polypropylene fiber is a man-made fiber produced from a thermoplastic polymer called polypropylene (PP). It does not absorb water. It does not rust. It stays stable in most cement environments.

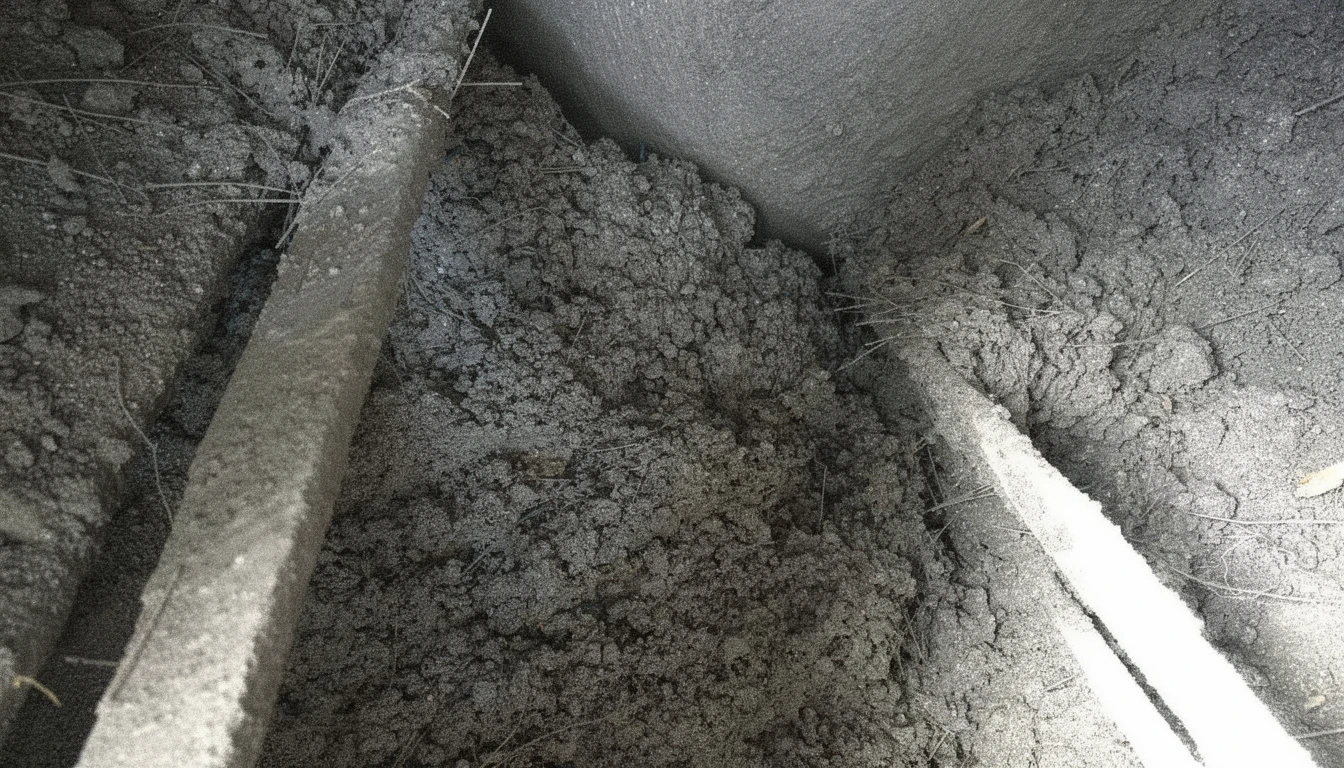

In construction, polypropylene fiber is usually sold as short cut fibers. You add them into the mix during batching. The fibers spread through the paste, then form a small “net” inside the hardened product.

What does polypropylene fiber look like?

Polypropylene fiber can look very different based on its type. The two most common categories are micro fiber and macro fiber.

- Micro polypropylene fiber: very thin, short, hair-like strands. It is used for early-age crack control.

- Macro polypropylene fiber: thicker, longer strands. It is used for toughness and post-crack performance.

You may also see these product forms:

- Monofilament fiber: single smooth filaments. It disperses well. It is common for plastic shrinkage control.

- Fibrillated fiber: a film that opens into a mesh-like shape during mixing. It creates more surface area in the paste.

Micro fiber mainly targets plastic shrinkage cracks near the top surface. Macro fiber targets load-related cracking after the concrete hardens.

How is polypropylene fiber made?

Polypropylene fiber starts as polypropylene resin pellets. Manufacturers melt the resin, then extrude it through small openings. After that, the material is drawn to reach the target diameter. Then it is cut to length.

Some fibers receive surface treatment to improve bonding with cement paste. Some fibers are embossed or shaped to improve mechanical anchoring inside concrete.

From a buyer’s view, the manufacturing method matters for consistency. A stable production line helps control:

- fiber length tolerance

- diameter stability

- clean cutting with low dust

- dispersion behavior in mixers

These factors affect the final performance more than many buyers expect.

Why is polypropylene fiber used in concrete?

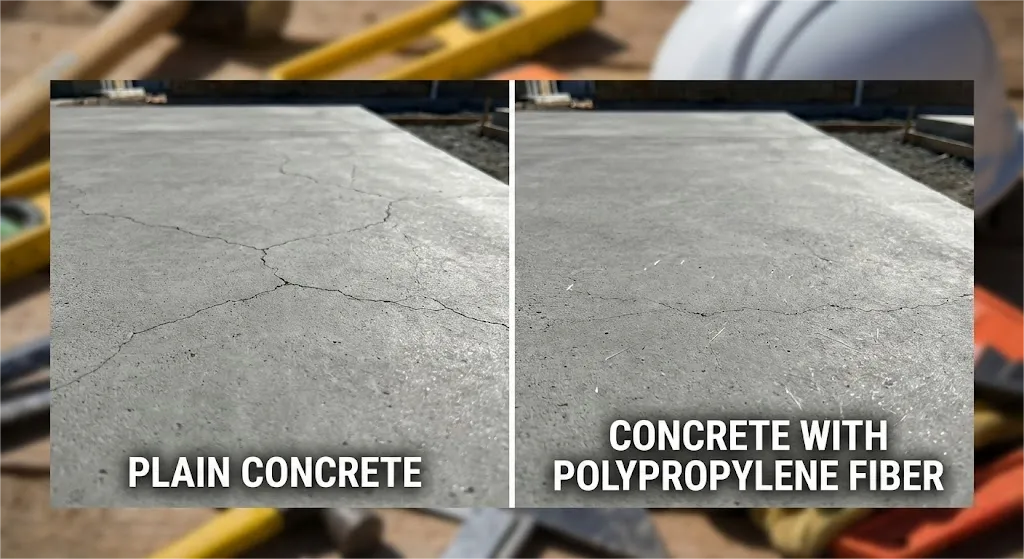

Concrete has strong compressive strength. It has weak tensile strength. Shrinkage, heat, and site drying can trigger cracks fast. Polypropylene fiber helps manage this crack behavior.

Key reasons people use polypropylene fiber in concrete:

- Plastic shrinkage crack control: micro fibers hold the early paste together while water leaves the surface.

- Better surface integrity: fewer micro cracks can reduce dusting, crazing, and edge chipping.

- Non-corrosive reinforcement: polypropylene does not rust, so it avoids corrosion-related staining.

- Chemical stability: it performs well in many environments where steel corrosion is a concern.

- Spalling reduction in fire (in some designs): micro fibers can create pressure-relief channels as they melt, which may reduce explosive spalling risk in dense mixes.

In marketing terms, polypropylene fiber is a low-cost add-on that improves “finish quality insurance.” It helps protect slab appearance, while also protecting your reputation.

Where is polypropylene fiber used?

Polypropylene fiber is used across many cement systems. It fits both ready-mix and dry-mix channels. It also fits precast factories.

Common use cases include:

- Slabs-on-ground: warehouses, logistics floors, workshops, parking areas

- Screeds and toppings: levelling layers, repair toppings, thin bonded overlays

- Shotcrete: tunnel linings, slope stabilization, repair shotcrete

- Precast elements: pipes, rings, covers, small panels, drainage products

- Mortar products: repair mortars, renders, tile adhesives, waterproof mortars

Micro polypropylene fiber is very common in general slabs and mortars. Macro polypropylene fiber is used when toughness matters, such as industrial slabs or pavements.

What is the typical dosage for polypropylene fiber?

Dosage depends on the fiber type and the goal.

Typical starting ranges:

- Micro polypropylene fiber: about 0.6–1.0 kg per m³ for plastic shrinkage crack control

- Macro polypropylene fiber: often 2–6 kg per m³ for toughness and residual strength targets

Dosage should follow project requirements, test data, and local design practice. Trial mixes matter. They confirm workability, finishing, and dispersion.

Practical mix tips that reduce problems:

- Add fibers slowly. Avoid dumping a full bag at once.

- Keep mixing time adequate to disperse the fibers.

- Use a water reducer if slump drops below target.

- Keep curing discipline. Fiber helps, but it does not replace curing.

What are the limitations of polypropylene fiber?

Polypropylene fiber is useful, but it is not magic.

Key limitations to state clearly:

- It does not replace structural rebar in most structural members. Beams, columns, suspended slabs still require steel reinforcement by design code.

- Micro fiber does not add major structural strength. It focuses on early crack control and surface durability.

- Too much fiber can hurt finishing. It can reduce workability, then cause surface drag during troweling.

- Poor mixing can cause clumps. “Fiber balls”reduce performance and create weak zones.

- Wrong product selection can disappoint. Using micro fiber in a job that needs toughness will not solve load cracking.

The best practice is simple. Use polypropylene fiber for what it does best. Use rebar for what it does best. Use both when the project needs both crack control and structural capacity.

How do you choose a polypropylene fiber supplier?

Many fibers look similar on paper. Real differences show up in dispersion, consistency, and service support.

A practical supplier checklist:

- Stable length and diameter control

- Clean cutting with low dust content

- Clear packaging label and batch traceability

- Technical data sheet with recommended dosage ranges

- Support for trial mix planning and site feedback

- Reliable lead times for repeat orders

For distributors, consistency is the main value. When the fiber is stable, complaints drop. Your customers reorder more often.

Ecocretefiber™ polypropylene fiber solutions

Ecocretefiber™ is the fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. We supply polypropylene fiber for concrete in both micro grades and macro grades. Our products are designed for ready-mix, precast, shotcrete, and dry-mix systems.

What customers typically want from us:

- product matching: micro vs macro selection

- dosage suggestion based on project type

- mixing and finishing tips for stable results

- documents for distributors: datasheets, packaging, marketing copy

If you sell fiber products, we also support distributor cooperation. If you run a plant, we support trial mixes and performance targets. The goal is simple. Your concrete looks better. Your slabs crack less. Your customer trust grows.

Conclusion

A polypropylene fiber is a synthetic reinforcement fiber made from polypropylene resin. In concrete, it helps control early cracking, improve surface integrity, and support durability. Micro fibers focus on plastic shrinkage crack control. Macro fibers focus on toughness after cracking. The right fiber type, dosage, and mixing method decide the result.

If you want polypropylene fiber that disperses well and performs consistently, Ecocretefiber™ can support your mixes with stable supply, technical guidance, and products designed for real construction work.