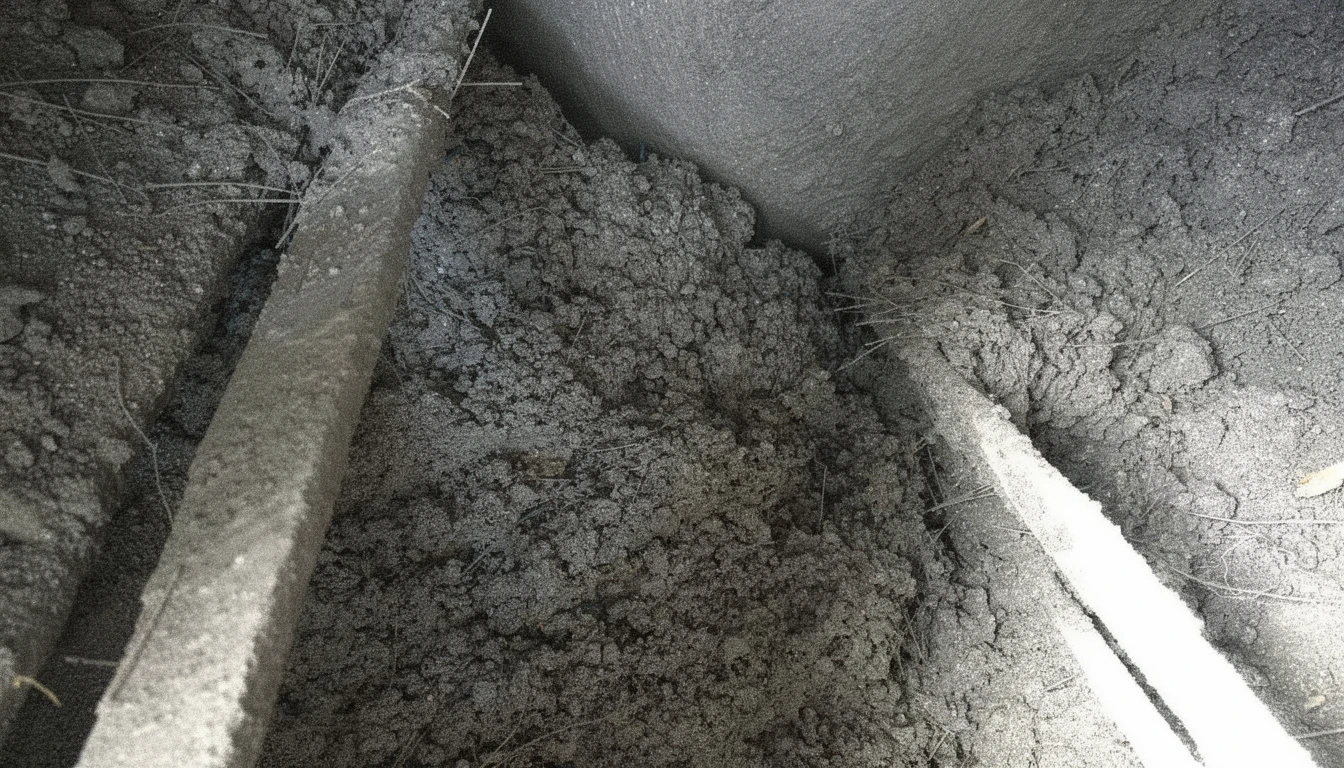

Polypropylene fiber reinforced concrete (often shortened to PPFRC) is concrete that contains short polypropylene (PP) fibers mixed through the batch. The fibers spread through the paste and aggregate. They create a three-dimensional reinforcement effect inside the concrete. This helps control cracking, improves toughness, plus supports durability in many common applications.

PPFRC is popular because it is easy to use. Fibers go into the mixer or ready-mix truck. Crews do not need to place a full mesh in many non-structural crack-control jobs.

What is polypropylene fiber reinforced concrete (PPFRC)?

PPFRC is a fiber-reinforced concrete that uses polypropylene fibers as the reinforcement element. The base material stays the same. It is cement, water, sand, coarse aggregate, plus admixtures when needed. The difference is that PP fibers are added during mixing.

The most practical way to describe PPFRC is simple. Rebar reinforces concrete in specific lines. PP fibers reinforce concrete across the full volume. That is why contractors use it for crack control and surface performance.

PPFRC is not one single product. Performance changes with fiber type, fiber dosage, mix design, placement method, curing method.

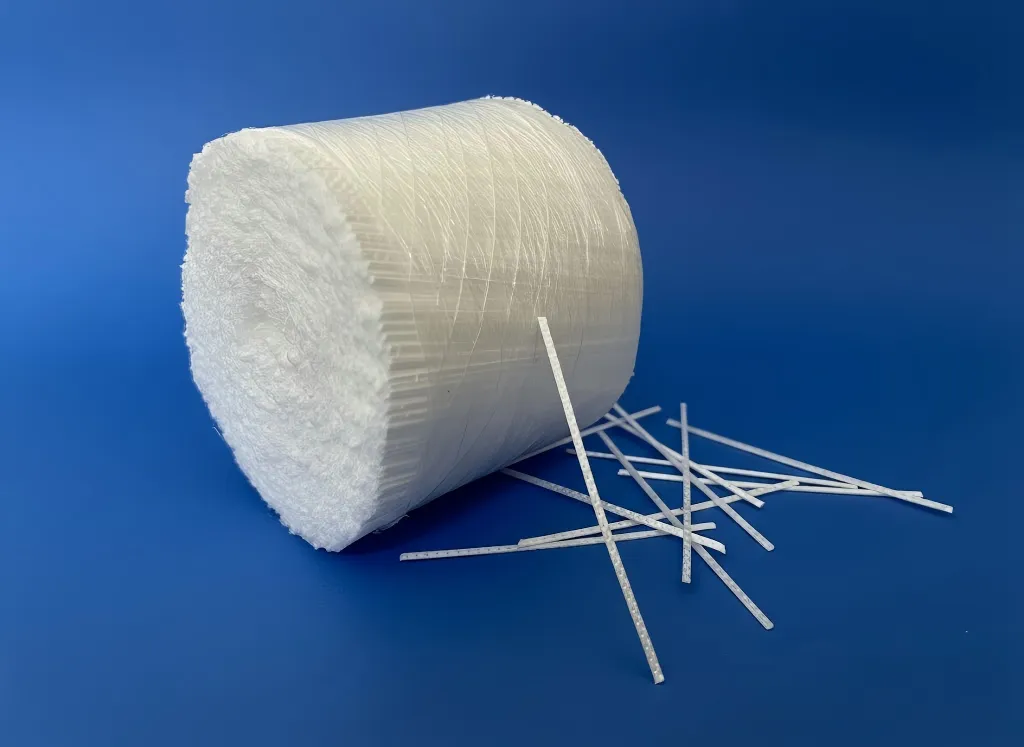

What are polypropylene fibers (micro vs macro)?

Polypropylene fibers for concrete usually fall into two groups.

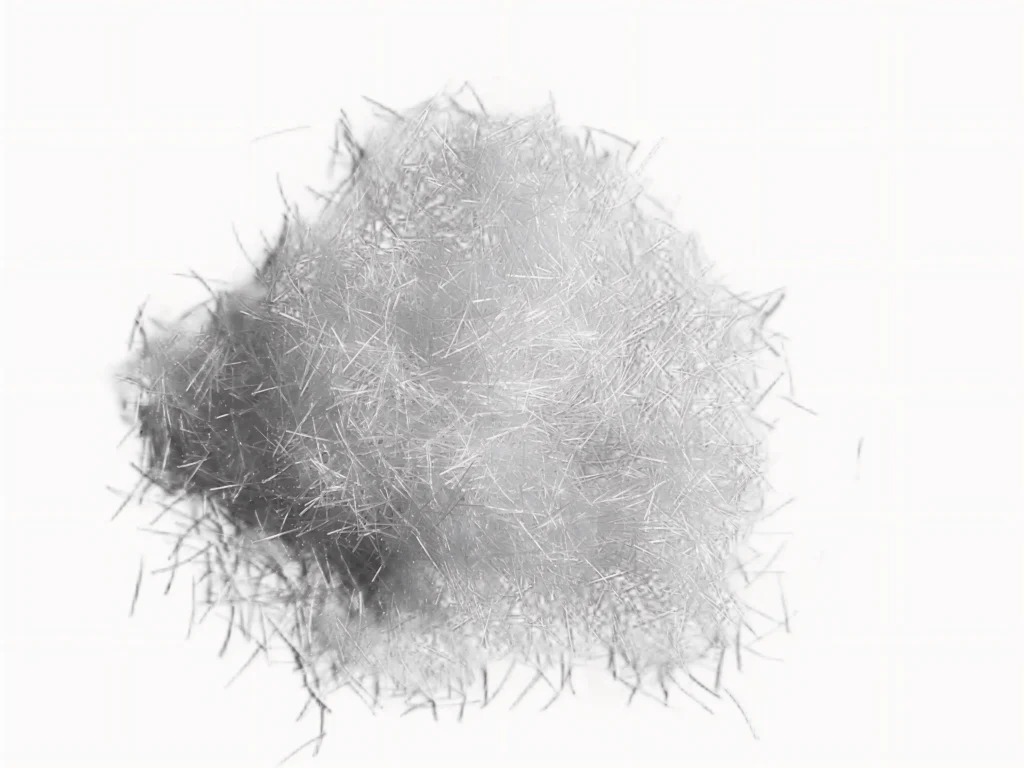

Micro polypropylene fibers are short and very thin. Their main job is fresh concrete performance. They reduce plastic shrinkage cracking. They also reduce plastic settlement by changing bleeding behavior.

Macro polypropylene fibers are longer, thicker, plus stiffer. Their main job is hardened concrete performance. They improve toughness, impact resistance, plus residual strength after cracking. Their structural contribution depends on dosage, fiber geometry, plus testing method.

In product form, you may also see:

- Monofilament: single smooth filaments, common for micro fiber crack control

- Fibrillated: film-like fiber that opens into a net during mixing, used for shrinkage crack control, plus cohesion support

How do polypropylene fibers work inside concrete?

PP fibers work mainly through crack bridging, plus mix stabilization.

In fresh concrete, micro PP fibers help reduce bleeding channels. They improve mix homogeneity. They slow bleed rate. This helps reduce plastic settlement issues. It also helps reduce plastic shrinkage cracking when evaporation is high.

In hardened concrete, macro PP fibers help after the first crack forms. Fibers cross the crack plane. They carry part of the tensile stress. This improves post-crack behavior, so the concrete behaves less brittle in many load cases. Research literature shows improvements in splitting tensile strength plus residual flexural strength at suitable fiber volume fractions.

PP fibers also have a special role in fire scenarios for dense mixes. PP melts at a relatively low temperature. This can create paths that relieve vapor pressure, which can reduce explosive spalling risk in some concretes, especially high-performance mixes used in tunnels.

What are the main benefits of PPFRC?

Most buyers choose PPFRC for clear, jobsite-level reasons. They want fewer cracks. They want fewer callbacks. They want a surface that lasts.

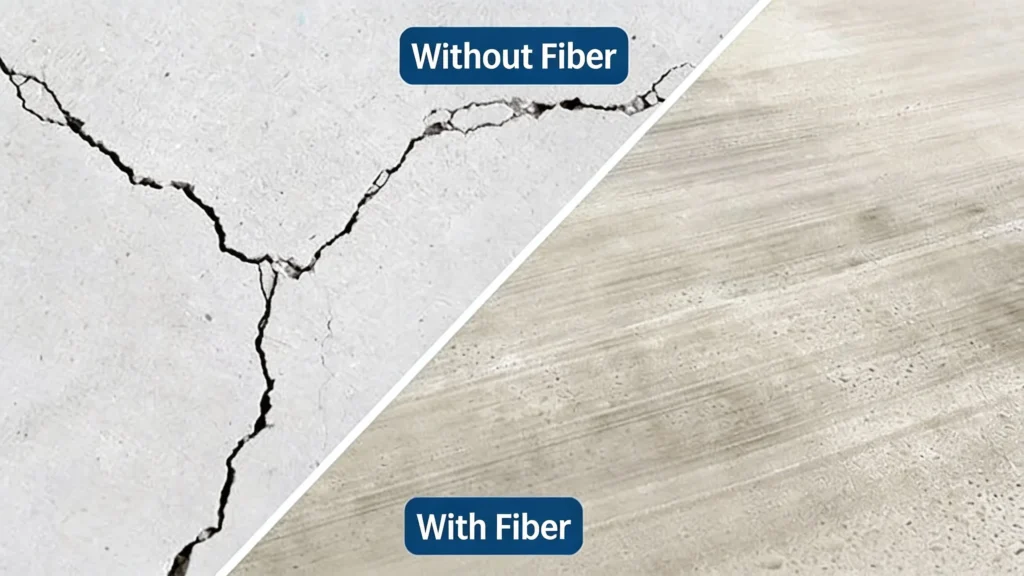

1) Better plastic shrinkage crack control

Polypropylene fibers are widely used to reduce early-age cracking caused by restrained plastic shrinkage. This is a known problem when the surface dries faster than bleed water can replace it.

2) Reduced segregation, reduced settlement issues

Micro PP fibers can help stabilize the mix. They block bleed water channels. This reduces bleed rate, plus supports more uniform finishing outcomes.

3) Higher toughness plus impact resistance

Macro PP fibers can improve toughness. They can improve residual flexural behavior after cracking, depending on dosage plus test method.

4) Durability support through tighter crack patterns

Tighter cracks mean less water movement through the slab. This supports long-term durability in many environments.

5) Fire spalling risk reduction in selected designs

PP micro fibers are used as a mitigation tool for explosive spalling in high-density concrete in fire exposure, especially in tunnel applications.

Where is polypropylene fiber reinforced concrete used?

PPFRC is used across ready-mix, precast, plus dry-mix systems.

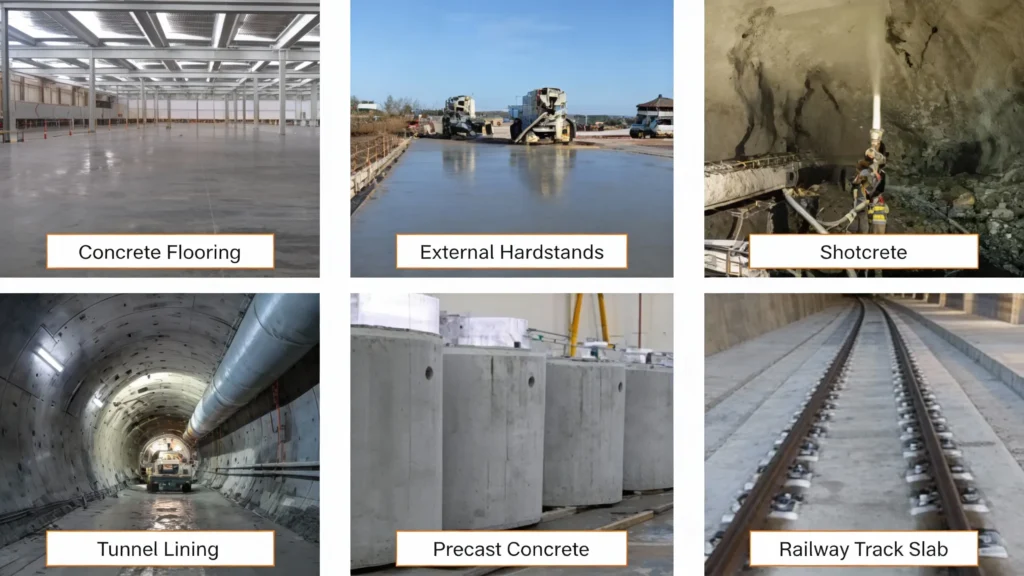

Common applications include:

- Slabs-on-ground: warehouses, workshops, yards, parking slabs

- Screeds plus toppings: thin layers that dry fast

- Shotcrete: repairs, slopes, tunnel linings (often combined with other reinforcement)

- Precast products: rings, covers, drainage units, small panels

- Mortars plus repair materials: bagged mixes that need shrinkage crack control

Micro PP fiber is usually selected for early crack control in slabs, screeds, plus mortars. Macro PP fiber is selected when the project needs higher toughness, plus better post-crack performance.

What is the typical dosage for PPFRC?

Dosage depends on fiber type, plus the target performance.

For micro polypropylene fibers, a typical reference dosage is about 0.9 kg/m³ for fresh concrete crack control.

Many products also list 0.6–0.9 kg/m³ as a common dosage band for plastic shrinkage crack control.

For macro polypropylene fibers, dosage is often higher. The correct number depends on required residual strength plus design method. Literature reviews emphasize that structural performance depends strongly on dosage plus fiber properties.

Mixing tips matter as much as dosage:

- Add fibers slowly. Do not dump all at once.

- Keep enough slump for dispersion. Some technical sheets warn against adding fibers to very low-slump mixes.

- Use a water reducer if measured slump drops after fiber addition.

- Keep curing strict. Fibers help, but curing still controls shrinkage risk.

![## What is the typical dosage for PPFRC?

Dosage depends on fiber type, plus the target performance.

For **micro polypropylene fibers**, a typical reference dosage is about **0.9 kg/m³** for fresh concrete crack control.

Many products also list **0.6–0.9 kg/m³** as a common dosage band for plastic shrinkage crack control.

For **macro polypropylene fibers**, dosage is often higher. The correct number depends on required residual strength plus design method. Literature reviews emphasize that structural performance depends strongly on dosage plus fiber properties.

Mixing tips matter as much as dosage:

- Add fibers slowly. Do not dump all at once.

- Keep enough slump for dispersion. Some technical sheets warn against adding fibers to very low-slump mixes.

- Use a water reducer if measured slump drops after fiber addition.

- Keep curing strict. Fibers help, but curing still controls shrinkage risk.

[Image Placeholder]

**Image Title:** Measuring PP Fiber Dosage at a Ready-Mix Plant

**Image Alt Text:** Technician weighing polypropylene fiber bags to achieve the correct dosage per cubic meter of concrete](https://ecocretefiber.com/wp-content/uploads/2025/12/Measuring-PP-Fiber-Dosage-at-a-Ready-Mix-Plant-1024x576.webp)

What are the limitations of PPFRC?

PPFRC is useful, but you should set expectations correctly.

- It does not replace structural rebar in most structural members. Rebar carries large tensile forces in defined locations. PP fibers are distributed. They improve crack control and toughness, but they are not the same as primary steel reinforcement.

- Micro PP fiber mainly targets early cracking, not structural strength. Micro fibers focus on fresh concrete behavior. They reduce plastic shrinkage cracking.

- Workability can change. Fibers may cause an apparent slump loss. Many suppliers recommend water reducers to offset this, not extra water.

- Wrong mixing can create clumps. Poor dispersion reduces performance. It also creates weak zones.

A simple rule works well. Use PPFRC to improve crack performance plus durability. Use rebar when the design needs clear tensile capacity.

What standards or tests apply to PPFRC?

If you use macro PP fibers for performance claims beyond plastic shrinkage control, testing matters.

Residual flexural performance is often evaluated using standardized beam tests. Common methods include EN 14651 plus ASTM methods such as ASTM C1609. Technical literature discusses how different test methods can change reported residual strength values, even for similar polypropylene fiber mixes.

For projects that aim to replace mesh in slabs-on-ground, your design team should use a recognized method. Your fiber product should provide test data, plus technical documentation.

Ecocretefiber™ polypropylene fiber reinforced concrete support

Ecocretefiber™ is the concrete fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. We supply polypropylene fibers for concrete in micro grades plus macro grades for global customers.

Our support focuses on practical delivery:

- Fiber selection for your target: micro crack control, macro toughness, or hybrid

- Dosage suggestions based on your application, plus your mixing conditions

- Mixing guidance that reduces clumping risk

- Documentation support for bids, distribution, plus product marketing

If you are building a fiber product line, we support distributor cooperation. If you are running ready-mix or precast production, we support trial mixes plus stable repeat supply.

Conclusion

Polypropylene fiber reinforced concrete is concrete that includes polypropylene fibers distributed through the mix. Micro PP fibers help control early cracking, plus improve fresh concrete stability. Macro PP fibers improve toughness after cracking in many applications. PP micro fibers are also widely recognized for reducing fire spalling risk in dense concrete in some designs.

If you want a straightforward way to reduce crack risk, improve surface performance, plus add value to your concrete products, PPFRC is often a strong choice. The right fiber type, dosage, plus mixing discipline decide the final result.