UHPC means Ultra-High-Performance Concrete. Normal concrete is the standard concrete used for most slabs, beams, columns, and foundations. The key difference is not only strength. The bigger difference is how the material behaves after cracking, plus how well it blocks water and salts over long service life. UHPC usually needs strict production control. Normal concrete is more forgiving, cheaper, plus easier to source at scale.

Below is a practical comparison that helps you choose the right material for your project.

What is normal concrete?

Normal concrete is the mainstream cement-based building material used in daily construction. It uses cement, water, fine aggregate, coarse aggregate, plus admixtures when needed. Its compressive strength varies by design, but many general-use mixes fall in the 20–40 MPa range.

Normal concrete works well because it is easy to batch, easy to place, plus cost-effective. It is also easy to reinforce with rebar. That is how most structural concrete systems handle tension.

Where normal concrete is common

- residential foundations

- beams and columns with rebar

- slabs-on-ground

- pavements

- retaining walls

What is UHPC?

UHPC is an advanced cementitious composite. It is usually fiber reinforced, has a very low water-to-binder ratio, plus uses optimized particle packing. FHWA describes UHPC as a cementitious composite with w/cm below 0.25, plus a high percentage of discontinuous internal fiber reinforcement. FHWA also notes UHPC compressive strength above 150 MPa, plus sustained post-cracking tensile strength above 5 MPa, with a discontinuous pore structure that reduces liquid ingress.

ACI 239R-18 gives a similar scope. It limits UHPC to concrete with minimum specified compressive strength of 150 MPa, plus specified durability, tensile ductility, plus toughness requirements. ACI notes fibers are generally included to meet those requirements. ACI also highlights very low permeability due to a dense, discontinuous pore structure.

UHPC is often produced with cement, silica fume, fine quartz sand, high-range water reducers, plus fibers. ACI reports typical water-binder ratios around 0.15–0.25. ACI also notes UHPC often uses fiber contents of 2% or more by volume, since fibers drive tensile ductility.

Difference #1: Mix design and ingredients

Normal concrete uses coarse aggregate as a major skeleton. This reduces paste content, plus reduces cost. The mix is designed to meet workability, strength, plus durability requirements, but it typically has a broader tolerance for field variation.

UHPC usually shifts the strategy. It often reduces or eliminates coarse aggregate in the matrix to improve homogeneity. It relies on particle packing across fine sizes to reduce void space. ACI summarizes three core principles: higher homogeneity, higher density through packing, plus higher ductility through fibers.

FHWA also frames UHPC as an optimized gradation system with low w/cm, plus a high volume of fiber reinforcement.

Practical result on site

- Normal concrete can be delivered by most ready-mix plants with standard controls.

- UHPC often needs tighter raw material control, tighter moisture control, plus higher mixing energy. ACI notes UHPC mixing is different and needs extra energy due to limited water plus little coarse aggregate.

Difference #2: Strength and cracking behavior

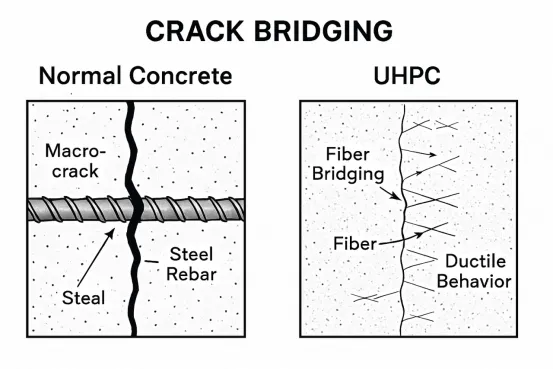

Normal concrete has good compressive strength. It has weak tensile strength, so it cracks under tension. In structural design, rebar carries most tensile forces. Concrete carries compression.

UHPC pushes both compressive strength and post-crack tensile performance much higher. FHWA reports UHPC compressive strength above 150 MPa, plus sustained post-cracking tensile strength above 5 MPa.

ACI also highlights tensile ductility, plus strain-hardening or elastic-plastic behavior under uniaxial tension in typical UHPC formulations.

What this means in practice

- Normal concrete cracks earlier under tension, so crack control depends heavily on rebar layout, cover, plus detailing.

- UHPC can carry tensile stress after cracking because fibers bridge cracks. Crack widths can stay tight, plus the material can absorb more energy before failure.

UHPC does not remove the need for engineering. It changes what is possible. It can also let designers reduce some conventional reinforcement in specific elements when the design method allows it. ACI notes steel fibers can improve ductility, plus can eliminate some mild steel reinforcement in certain cases.

Difference #3: Durability and permeability

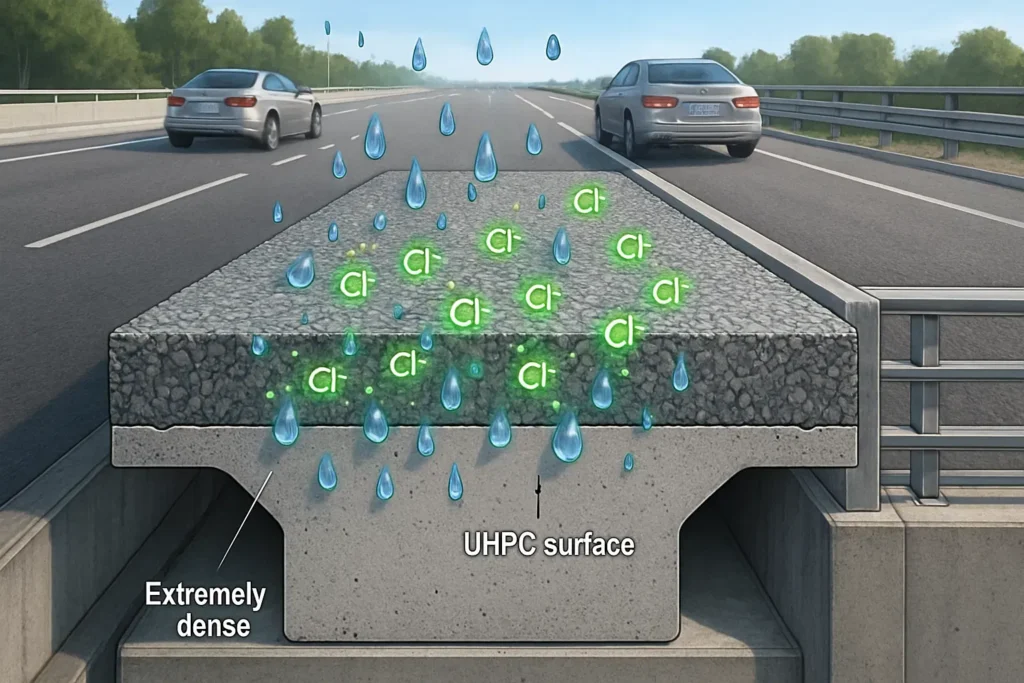

Normal concrete can be durable, but durability depends on water-cement ratio control, curing discipline, cover thickness, plus exposure class design. If cracks open wide, water plus chlorides can reach steel faster. That raises corrosion risk.

UHPC is widely recognized for very low permeability. FHWA links this to a discontinuous pore structure that reduces liquid ingress.

ACI also states UHPC has very low permeability due to a dense, discontinuous pore structure.

There is also strong test evidence behind this claim. In FHWA’s UHPC material property characterization work, Graybeal reported rapid chloride penetrability (ASTM C1202) below 50 coulombs for steam-treated UHPC, plus much lower values over time for untreated UHPC as it matured.

Where this matters most

- marine zones

- de-icing salt exposure

- chemical splash zones

- freeze-thaw regions with high moisture

- bridge joints and closure pours, where leakage is common

Difference #4: Production, curing, and quality control

Normal concrete production is standardized. Most plants can deliver it with routine QC. Placement and curing still matter, but the workflow is familiar.

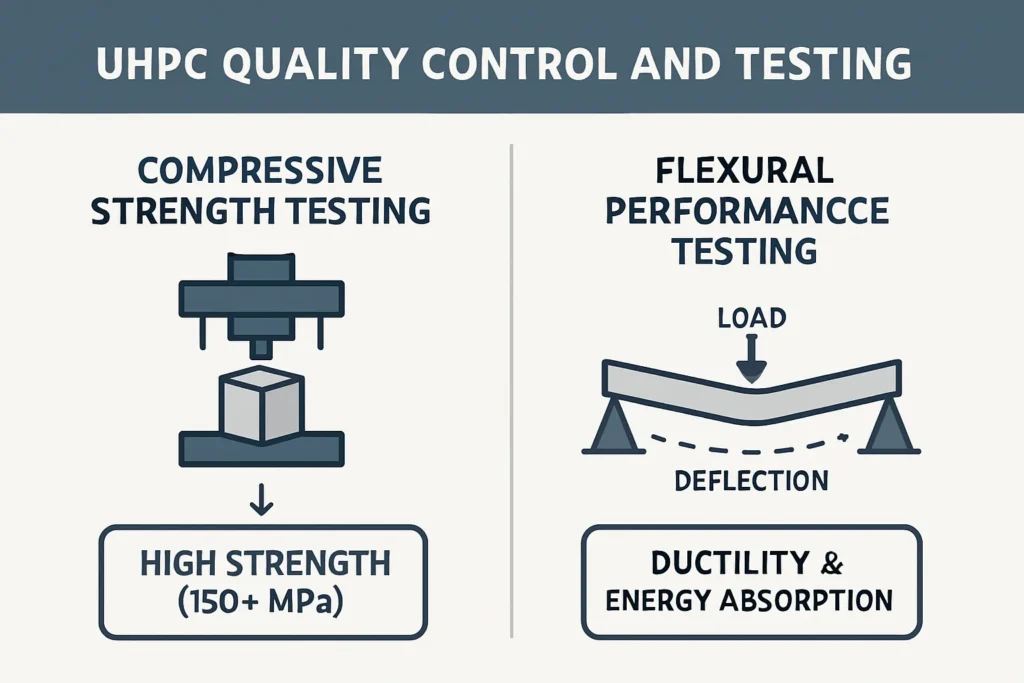

UHPC needs tighter process control. ACI explains that UHPC includes limited water plus little coarse aggregate, so mixing requires extra energy to disperse water and overcome low internal mixing action.

UHPC also has more formal testing pathways in many projects. ASTM C1856/C1856M is a widely referenced practice for UHPC specimen fabrication and testing. A public standard summary notes it applies to UHPC with specified compressive strength of at least 120 MPa, plus nominal maximum aggregate size below 5 mm, plus a defined flow range.

Practical impact

- UHPC demands strong batching discipline.

- UHPC benefits from trial mixes, plus consistent curing plans.

- UHPC often needs trained crews for mixing, placement, plus finishing.

Difference #5: Cost and value

Normal concrete wins on material cost. It is widely available. It fits most structural needs when reinforced with steel.

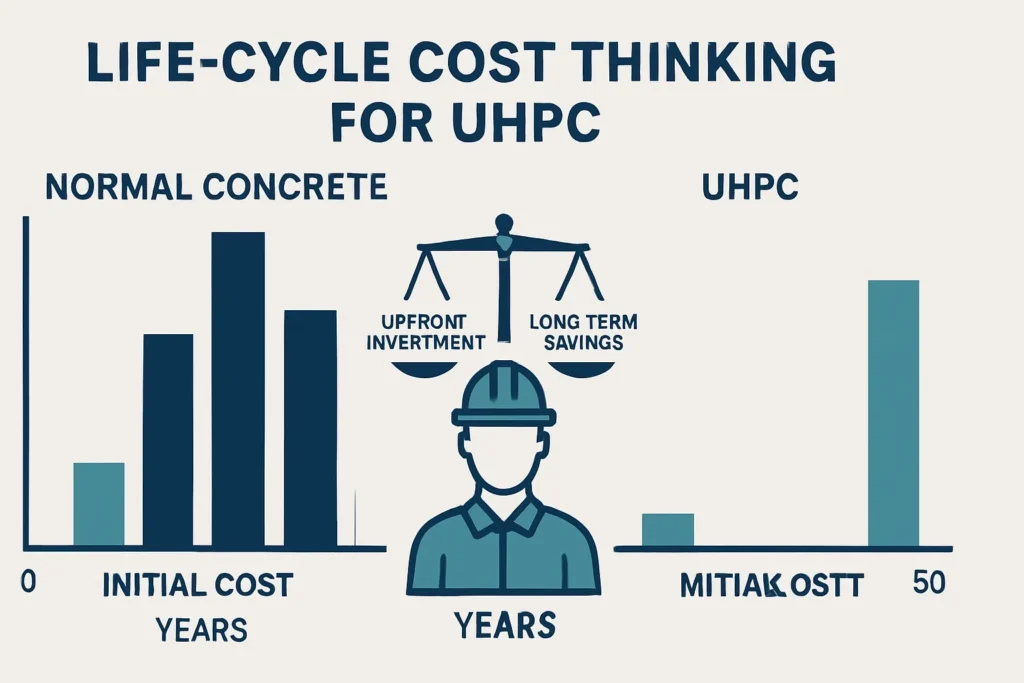

UHPC costs more. ACI explicitly notes UHPC cost is high compared with conventional concrete, so its use should focus on applications that engage several of its beneficial properties at once.

So the decision is rarely “UHPC everywhere.” The decision is usually “UHPC where it saves life-cycle cost.”

When UHPC can be cost-effective

- thinner sections that reduce dead load

- durable overlays that extend service life

- closure pours that reduce leakage problems

- elements where corrosion repairs are expensive

- projects where downtime cost is high

Where UHPC makes sense, where normal concrete makes sense

Normal concrete is the default choice for most structures. It is economical. It is proven. It is easy to source.

UHPC is a strategic choice. It is best when you need multiple advantages at the same time: high strength, high durability, tight crack control, plus long service life.

Choose normal concrete when

- the structure is standard

- rebar detailing is straightforward

- exposure is moderate

- supply chain simplicity matters

- budget is tight

Choose UHPC when

- durability drives the business case

- you need slender elements

- you need high tensile performance from the material system

- corrosion risk is high

- closure pours or joints must stay watertight

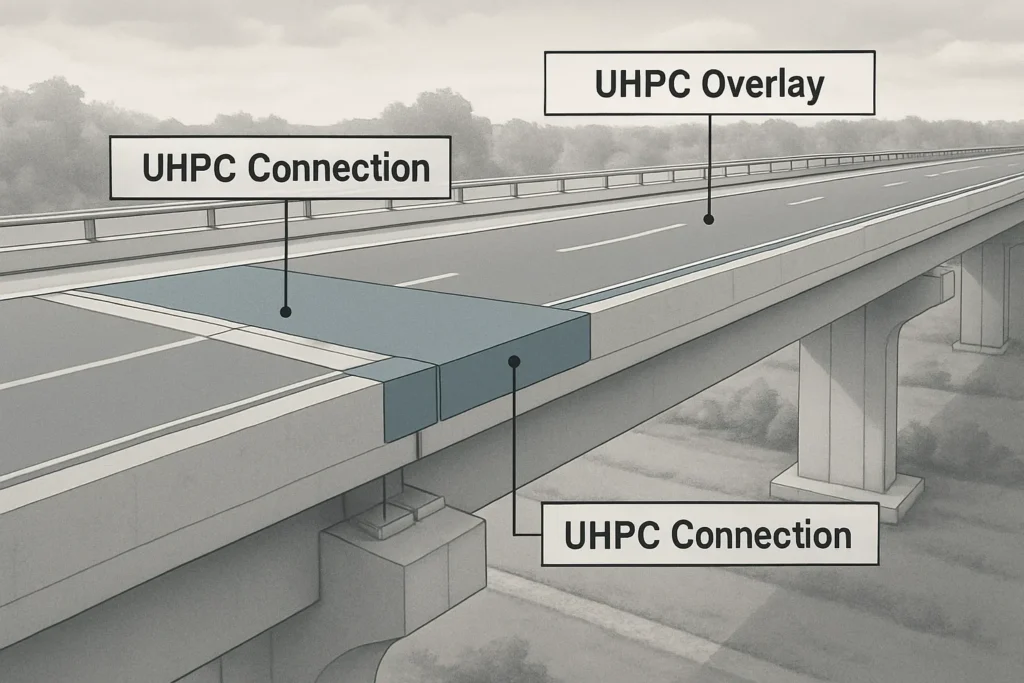

FHWA highlights UHPC for bridge infrastructure solutions, including thin overlays, claddings, shells, plus field-cast connections between precast elements.

Expert guidance: fiber choices for UHPC projects

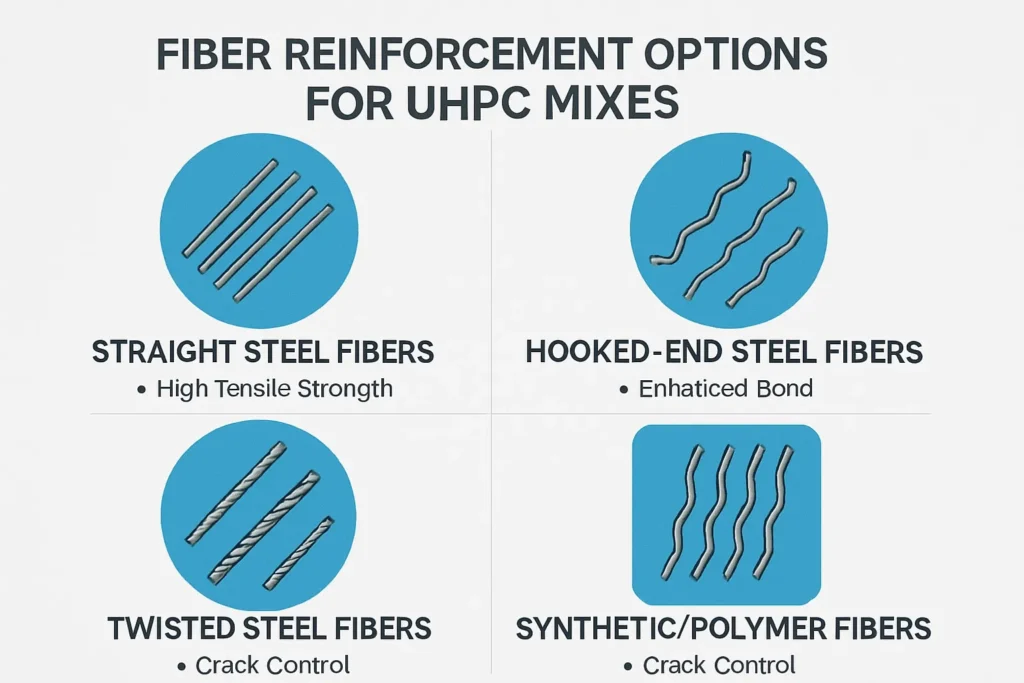

UHPC performance relies heavily on fibers. ACI notes ductility enhancement comes from fibers, with typical fiber contents of 2% or more by volume, while maximum content depends on fiber shape, aspect ratio, plus workability limits.

That makes fiber selection a real engineering lever. It impacts tensile behavior, crack width control, mixing energy, plus finish quality.

What a good UHPC support process looks like

- define exposure, plus target life

- define tensile performance needs, not only compressive strength

- select fiber type, plus geometry based on that target

- run trial mixes for flow, fiber dispersion, plus early-age behavior

- verify performance with accepted tests for the project scope

Ecocretefiber™ support

Ecocretefiber™ is the fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. If you are developing UHPC-style mixes, we can support fiber selection, dosage planning, plus mixing guidance, then move into stable supply for repeat production. This is most useful for precast plants, plus contractors who want consistent closure pours or durable repair solutions.

Conclusion

The difference between UHPC and normal concrete is bigger than compressive strength. Normal concrete is the standard choice because it is economical, widely available, plus easy to build with. UHPC is a dense, fiber-reinforced composite with very high strength, sustained post-crack tensile capacity, plus very low permeability.

UHPC makes the most sense when durability and long service life justify the higher material cost. Normal concrete remains the best fit for most conventional structures. The best projects use each material where it delivers the most value.