Concrete is strong in compression. Concrete is weak in tension. Cracks can appear early, sometimes within hours of placement. Cracks can also grow later under traffic, impact, or temperature movement. Polypropylene (PP) fibre is used because it reduces some of these risks with a simple step. The crew adds fibres during mixing. The fibres spread through the full volume. This creates “distributed reinforcement,” which supports crack control and toughness in many common jobs.

PP fibre is used most often for early-age crack control, plus fresh concrete stability. It is also used in fire design for dense concrete, especially in tunnel work, where PP fibres help reduce explosive spalling risk.

What is polypropylene fibre for concrete?

Polypropylene fibre for concrete is a synthetic fibre added to the concrete mix. Fibres can be “micro” or “macro.” The size changes the job the fibre can do.

ACI defines microsynthetic fibres as fibres with equivalent diameter less than 0.3 mm. ACI defines macrosynthetic fibres as fibres with equivalent diameter greater than 0.3 mm. ACI also notes polypropylene fibres can be either microsynthetic or macrosynthetic.

A practical way to view this on site is simple:

- Micro PP fibre targets fresh concrete behaviour. It mainly targets plastic shrinkage cracking, plus plastic settlement.

- Macro PP fibre targets hardened concrete behaviour. It supports toughness, plus post-crack control at higher dosage levels.

Reason 1: Polypropylene fibre reduces plastic shrinkage cracking

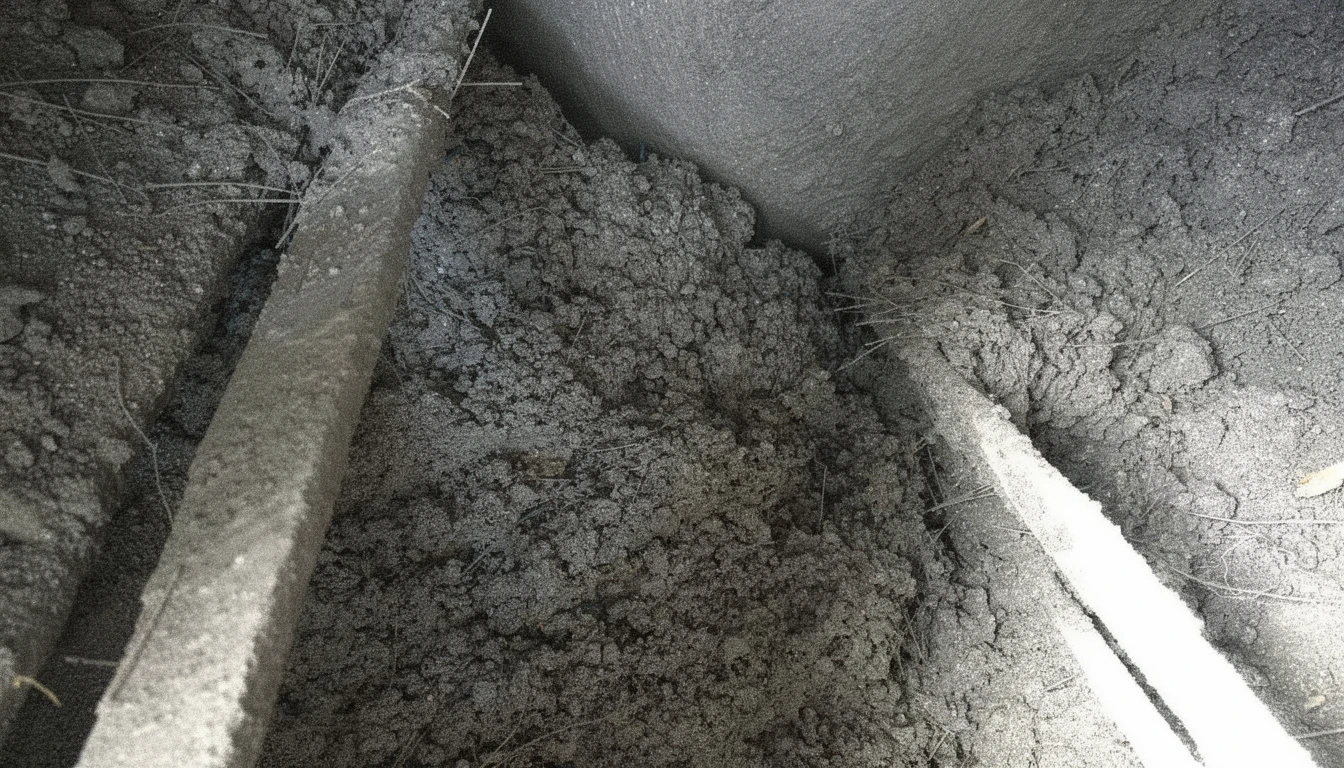

Plastic shrinkage cracks form soon after placement, while the concrete is still plastic. NRMCA explains that plastic shrinkage cracking becomes more likely when evaporation removes water from the surface before the slab sets. NRMCA also notes that synthetic fibre reinforcement can help resist the tension while the concrete is very weak.

NRMCA also recommends considering synthetic fibres (ASTM C1116) as one method to minimise plastic shrinkage cracking.

This is why PP fibre is common in:

- slabs-on-ground in hot or windy weather

- thin toppings that dry fast

- pavements and flatwork with large surface area

PP fibre does not replace curing. PP fibre reduces risk. A good curing plan still decides the final outcome.

Reason 2: Polypropylene fibre improves cohesion and reduces plastic settlement cracking

Many contractors buy PP micro fibres for one reason. They want a more stable mix during placement.

The Concrete Society explains that polypropylene micro-fibres increase mix homogeneity. The fibres help stabilise movement of solid particles. The fibres block bleed water channels. This reduces bleed capacity, slows bleed rate, plus helps reduce plastic settlement.

This effect matters when the mix is sensitive to finishing timing. It also matters around reinforcement, inserts, plus form edges where settlement cracks are common. NRMCA lists reduction of plastic settlement cracking, plus improved internal support and cohesiveness, as key reasons to use synthetic fibres.

So PP fibre is used in concrete when the buyer wants:

- fewer settlement cracks around rebar

- more stable surface mortar

- fewer bleed-related weak layers

Reason 3: Polypropylene fibre can increase toughness and impact resistance

Some PP fibre products focus on toughness rather than only early cracking. This is usually a macro-synthetic approach.

NRMCA lists “greater toughness and resistance to impact” as a use case for synthetic fibres.

ACI also states that fibre addition can improve properties such as impact resistance, toughness, plus ductility, depending on fibre material, geometry, plus addition rate.

This value is practical in:

- warehouse floors with forklift traffic

- slabs that see dropped loads

- pavements with hard wheel loads

- precast pieces that chip during handling

A buyer should align expectations with the fibre type. Micro PP fibres have limited post-crack ductility in many mixes, according to the Concrete Society.

Macro PP fibres can target post-crack control, but they require the right dosage, plus test documentation.

Reason 4: Polypropylene fibre supports difficult placement methods

Some concrete placements fail because the mix does not “hold together” during delivery. Some placements fail because the crew needs steep slopes, thin sections, or spray application.

NRMCA lists internal support and cohesiveness as a reason to use synthetic fibres. NRMCA highlights use in steep inclines, shotcrete, plus slip-formed placements.

This is not a marketing theory. This is a site workflow benefit. Fibre reinforcement can reduce segregation risk in some conditions. It can also make the mix more forgiving when placement is fast.

Common examples include:

- shotcrete repair work

- slope protection

- slip-form paving

- thin overlays

Reason 5: Polypropylene fibre helps reduce explosive spalling risk in fire

This is one of the highest-value reasons to use PP fibre, but it applies most to dense concrete.

In fire, moisture inside concrete turns into vapour. Vapour pressure can build in low-permeability concrete. This can trigger spalling. A technical paper on PP fibres states the use of polypropylene fibres to inhibit explosive spalling is becoming common practice in many parts of the world, with tunnel construction as a key driver.

Peer-reviewed literature also reports that adding PP fibres gives promising results for spalling mitigation in fire exposure.

The mechanism is widely explained in simple terms. As temperature rises, PP fibres melt. This can create connected pathways for vapour to escape. This reduces pore pressure build-up. The review article discusses how PP fibres reduce pore pressure, plus how permeability increases rapidly with temperature in fibre mixes.

This is why many specifications include PP micro fibres for:

- tunnel linings

- high-performance concrete elements with fire requirements

- dense mixes where spalling risk is a known hazard

Typical dosage: what buyers use in real projects

Dosage depends on fibre size, plus the target benefit.

Micro PP fibre for fresh concrete crack control

The Concrete Society notes polypropylene micro-fibres are typically added at about 0.9 kg/m³. It also explains their primary role is to modify fresh concrete properties such as bleed channel control and plastic settlement reduction.

ACI lists a typical range for microsynthetic fibres of 0.05% to 0.2% by volume. ACI also provides an equivalent mass range of 0.44 to 1.8 kg/m³ for microsynthetic fibres.

Macro PP fibre for toughness and post-crack control

NRMCA states macro-synthetic fibres are thicker and used at a higher dosage rate of around 5 lb/yd³, which is about 3.0 kg/m³.

ACI lists typical macrosynthetic fibre dosages of 0.2% to 1% by volume, plus an equivalent mass range of 1.8 to 9 kg/m³.

A good buyer does not guess dosage. A good buyer ties dosage to the problem, then verifies by trial pours or performance tests.

What polypropylene fibre should not be used for

PP fibre is not a replacement for every reinforcement system. Buyers need this clarity before they write a spec.

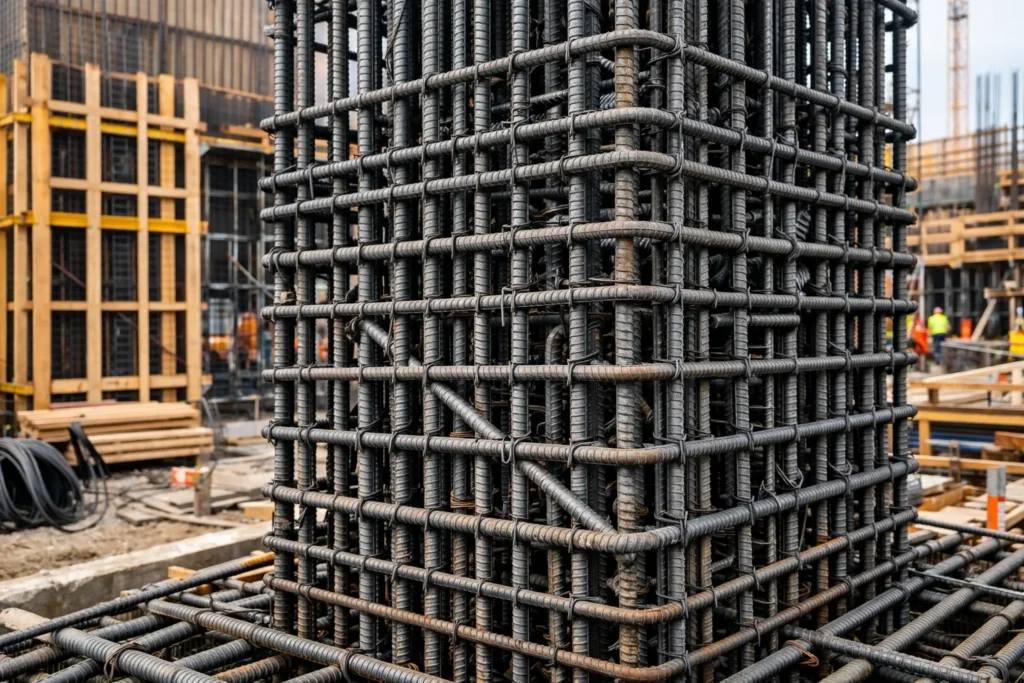

NRMCA lists “Do Not Use Synthetic Fibres For” items. These include replacement of any moment-resisting or structural steel reinforcement. NRMCA also states synthetic fibres should not be used for higher structural compressive or flexural strength development.

So the correct message is direct:

- PP fibre helps crack control, plus toughness.

- Rebar still carries structural tension in most structural members.

- A slab design still needs proper thickness, subbase, plus joint plan.

Polypropylene fibre vs other fibres: why PP is often the first choice

Some projects need a fibre with high stiffness and higher tensile modulus for load transfer. Some projects need fire spalling mitigation. Some projects need early crack control at low cost.

Sika’s fibre handbook states that when the goal is to reduce plastic shrinkage and settlement cracking, the most widely used material is polypropylene. Sika links this to availability and commercial viability. The same handbook notes that fire protection and spalling reduction call for fibres with a low melting point, such as polypropylene or PVA.

This gives a clean buying logic:

- Choose PP micro fibre when the main goal is early crack control plus fresh mix stability.

- Choose PP macro fibre when the main goal is toughness or post-crack control in slabs. Use documentation and tests.

- Choose PP micro fibre for fire spalling mitigation in dense mixes when the design calls for it.

Expert guidance: how to specify PP fibre with fewer site problems

Most “fibre problems” are not fibre problems. They are process problems. The fix is a simple workflow.

- Define the failure you want to reduce: plastic shrinkage, settlement, impact, or fire spalling.

- Select micro vs macro using clear definitions. ACI gives the 0.3 mm threshold.

- Set a dosage that matches the goal. Use recognised guidance ranges.

- Control dispersion. Follow a controlled adding method. Extend mixing time if needed. ACI highlights the need for mixing techniques that achieve uniform mixtures.

- Keep curing strict. Fibres reduce risk, but curing still prevents drying stress.

Ecocretefiber™ | Shandong Jianbang Chemical Fiber Co., Ltd.

Ecocretefiber™ supports project matching first. We help customers choose PP micro fibre or PP macro fibre based on real site goals. We then support dosage suggestions, mixing guidance, plus documentation for distribution or bidding.

Related Products

- Polypropylene Micro Fibre (Monofilament / Fibrillated)

- Polypropylene Macro-Synthetic Fibre

- PVA Fibre for Cementitious Composites

- AR Glass Fibre for GRC Systems

Conclusion

Polypropylene fibre is used in concrete because it solves common, costly problems with a simple change at batching. It reduces plastic shrinkage cracking while concrete is still weak.

It improves cohesion and helps reduce plastic settlement cracking by stabilising solids and blocking bleed channels.

It can improve toughness and impact resistance when the fibre type and dosage target that goal.

It is also widely used to reduce explosive spalling risk in fire for dense concrete, especially in tunnel applications.

For best results, the buyer should match fibre type to the job, set dosage with credible guidance, then control mixing and curing on site.