Concrete slabs often crack and show ugly hairs from old fibers. I felt stuck with this until I tried stealth macro synthetic fiber in my own floor projects.

Yes, Ecocretefiber™ stealth macro synthetic fiber can replace many traditional fibers in slabs on ground. It keeps fibers hidden below the surface, still controls cracking, and cuts grinding work on finished concrete floors.

That answer sounds bold, so I tested it on my own jobs. I watched how stealth macro synthetic fiber behaved from the mixer to the final trowel pass on fresh slabs.

What problems did traditional concrete fibers cause on my finished slabs?

On my early projects I always felt nervous at handover. The slabs were strong, but the surface looked rough because stiff fibers kept showing through the hardened concrete.

Traditional twisted bundle fibers, synthetic pp macrofiber, and fibrillated mesh fibers all helped with cracking, but many fiber ends sprang back during finishing and stayed visible on slabs, paths, and pavements.

How did the three common polypropylene fibers behave in my work?

When I started pouring fiber concrete, I followed what other contractors did. I used three main polypropylene fibers. Each type came from a different supplier, and each looked different in the bag, but they all had the same habit. They loved to straighten themselves. When I bent them in my hand they always tried to go back to a straight line. That same habit showed up in the slab. It helped bridge micro cracks, but it hurt our finish.

| Fiber type | Typical form | Typical length range | Effect on surface in my jobs |

|---|---|---|---|

| Synthetic PP macrofiber | Flat or embossed macro fiber | 30–60 mm | Strong, but many ends stayed visible |

| Twisted bundle PP fiber | Twisted macro bundles | 40–56 mm | Bundles opened and some strands appeared |

| Fibrillated PP microfiber | Mesh or bundled mesh | 19–60 mm | Fine hairs often rose to the surface |

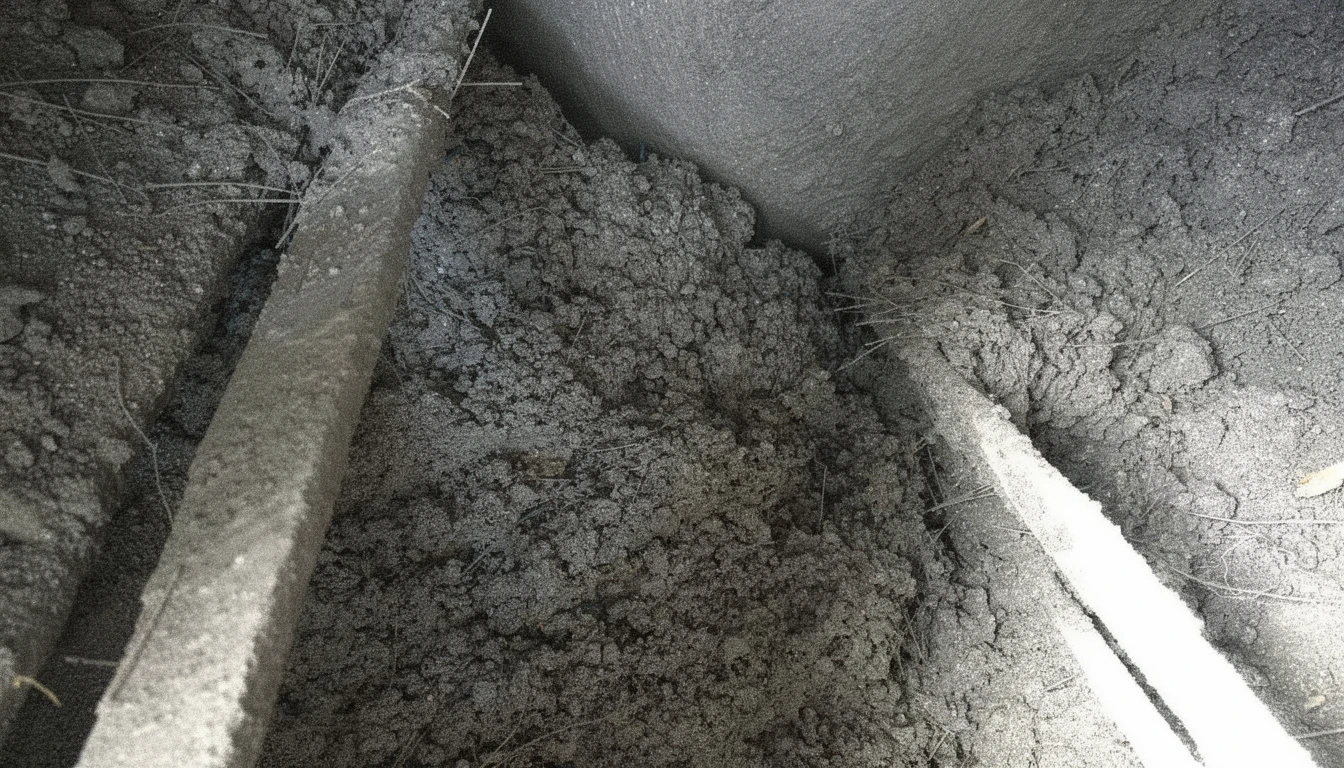

On slabs on ground, footpaths, toppings, pavements, shared paths, stencil concrete, roads, and cycleways, these fibers did reduce plastic shrinkage and improved toughness. However, after vibration and troweling, the paste pulled upward while many fibers pushed back. The result was a “hairy” floor. To satisfy owners I often had to grind or burn off fibers. This extra work cost time, money, and trust. It also made me look for a better option like stealth macro synthetic fiber.

How does Ecocretefiber™ stealth macro synthetic fiber change slab finishing?

I wanted a fiber that still protected the slab but did not fight my finishers. I tried Ecocretefiber™ stealth macro synthetic fiber on a small test pour first.

Ecocretefiber™ stealth macro synthetic fiber uses a low memory, self-fibrillating design. During vibration and troweling it bends and stays bent inside the paste, so fiber ends remain hidden below the surface.

Why do I call it “stealth” in my own projects?

The first time I poured a slab with Ecocretefiber™ stealth macro synthetic fiber, I watched every step. The mix looked like normal fiber concrete coming out of the truck. The difference showed up during finishing. When we ran the trowel, the blades moved more smoothly. We felt fewer snags and drag marks. My finishers even asked if we had lowered the fiber dosage, but the mix design was the same.

| Property | Old macro PP fibers | Ecocretefiber™ stealth macro synthetic fiber |

|---|---|---|

| Memory after bending | High, tried to straighten | Low, stayed bent in the paste |

| Behavior during troweling | Ends often moved to the surface | Ends stayed inside the slab |

| Visible fibers after hardening | Many hairs on exposed concrete | Almost none on normal slabs |

| Need for post-grinding | Often needed on exposed floors | Greatly reduced or not needed |

After curing we checked the surface under bright light. The old control panel showed many white hairs, but the panel with stealth macro synthetic fiber looked like plain concrete. Lab tests later confirmed that compressive strength and post-crack toughness stayed in the same range as the old fibers. For me this meant I could keep strong slabs and remove the main reason owners complained about fiber concrete: the ugly surface.

Where should I use stealth macro synthetic fiber in real projects?

After those tests I began to choose stealth macro synthetic fiber whenever people would see the slab every day. I also checked how it behaved in different applications.

Stealth macro synthetic fiber works best in slabs on ground, industrial floors, paths, pavements, roads, and cycleways where owners care about both crack control and a clean, fiber-free surface.

How do different applications benefit from stealth macro synthetic fiber?

On each job I ask a simple question. What will the owner notice every day? The answer is almost always the surface they walk or drive on. With stealth macro synthetic fiber I can protect the slab from cracking and still keep that surface neat. I now use this fiber whenever appearance and durability must both be high.

| Application | How stealth macro synthetic fiber helps in my work |

|---|---|

| Slab on ground | Controls plastic shrinkage and gives post-crack toughness for long-lasting floors. |

| Footpaths | Prevents early-age cracking and supports long-term crack resistance with a clean surface. |

| Toppings | Increases tensile capacity and bond strength without extra grinding steps. |

| Pavements | Improves fatigue resistance and limits crack spread under traffic loads. |

| Shared user paths | Adds toughness and cuts maintenance from cracking and spalling along busy paths. |

| Stencil concrete | Protects decorative patterns from cracking without fibers spoiling the finish. |

| Pathways | Controls shrinkage cracks in thin sections and keeps surfaces smooth for walking. |

| Roads | Helps distribute loads and resist cracks in high-traffic lanes. |

| Cycleways | Enhances flexibility and toughness so riders enjoy a safe, even track over many years. |

On a warehouse project the client had suffered from hairy fibers on an older floor built by another contractor. I suggested a side-by-side trial. One bay used his usual twisted bundle fiber. Another bay used Ecocretefiber™ stealth macro synthetic fiber at a matching dosage. After curing, the traditional bay showed many visible fibers. The stealth bay looked like plain concrete, yet core tests showed similar strength. The client then chose stealth macro synthetic fiber for the whole job, and he has not called me back with complaints.

Conclusion

By using Ecocretefiber™ stealth macro synthetic fiber, I keep fibers hidden, cut finishing work, and still deliver strong, durable slabs and pavements that make both engineers and owners happy.