A lot of contractors lay concrete that looks great at first, but then it cracks and wears out too soon. Concrete fiber is an easy way to protect your work and keep your customers happy.

Basically, concrete fiber is made of small pieces of material that get mixed into concrete. It helps control cracking, makes the concrete stronger, and cuts down on how much maintenance it needs. There are different kinds of fiber for different jobs, budgets, and weight requirements, so planning ahead is key.

This guide will explain how fiber reinforcement works, what kinds of fiber are out there, and how to pick the right one for your projects. The goal is simple: finish jobs on time, make a profit, and give your customers concrete that lasts.

What’s Concrete Fiber Reinforcement?

Many folks still only think about rebar when reinforcing concrete. Once you get what fiber does, it becomes a handy tool you can use.

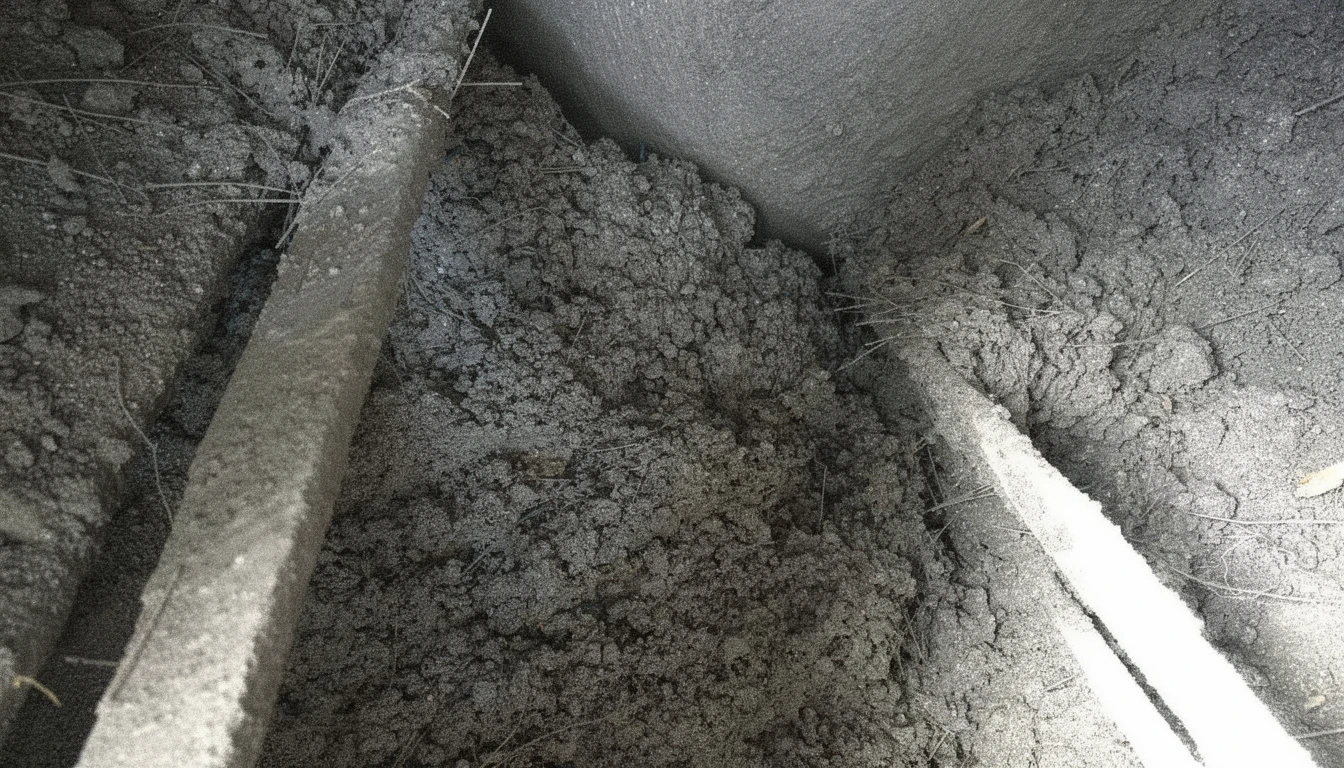

Concrete fiber reinforcement involves mixing lots of tiny fibers into the concrete. These fibers create a network that holds cracks together, spreads out weight, and improves how the concrete handles impacts.

Concrete is strong when it’s being squeezed (compression), but not so strong when it’s being pulled (tension). Small cracks can appear early on. When you add fibers, each one acts like a tiny anchor, grabbing onto the cement and other materials in the mix. As the concrete starts to crack, the fibers bridge the gap, share the stress, and prevent the crack from getting too big. This goes for both synthetic microfibers (which stop plastic shrinkage) and macro synthetic or steel fibers (which handle heavier loads). It doesn’t make concrete as strong as steel, but it does change how the slab breaks. Instead of one big crack, you get a bunch of tiny cracks that are hard to spot. That’s the idea behind Ecocretefiber™ products from Shandong Jianbang Chemical Fiber Co., Ltd., and that’s why more contractors are using fiber in floors, roads, and precast concrete.

How Concrete Fiber Acts?

Sometimes people add fiber and then get worried when the concrete looks different. This happens because fiber affects both fresh and hardened concrete.

When the concrete is fresh, fibers help reduce cracks from plastic shrinkage and water rising to the surface (bleeding). When the concrete has hardened, fibers make it stronger, more resistant to impacts, and more durable in the long run – especially when there’s heavy traffic.

Fibers get to work as soon as the fiber-reinforced concrete comes out of the truck. When the concrete is fresh, they hold everything together. They also shorten those plastic shrinkage cracks that show up while the surface is still wet. This makes the slab more even. The mix might seem a bit stiffer, but you can fix this by using the right water-reducing stuff and planning your finishing steps. Once the concrete hardens, fibers keep working. When there’s traffic and temperature changes, small cracks start to form. The fiber network holds these cracks together. The slab can handle more impact without breaking. Steel fibers make the concrete very strong after cracking, while macro synthetic fibers from Ecocretefiber™ don’t rust and work well in wet places. Whether the concrete is fresh or hard, good fiber design makes it easier to work with, protecting your timeline and reputation.

Main Types of Concrete Fiber:

When you first look at a fiber catalog, it can be confusing because there are so many choices. To make things easier, here’s a run down of the basic types.

Concrete fibers can be made from materials like polypropylene, PVA, PAN, UHMWPE, polyester, glass, basalt, steel, carbon, aramid, wood, and special mixes. Each material offers different cracking resistance, strength, temperature resistance, and cost.

The first big group is synthetic fibers. Polypropylene fibers are the most popular for stopping plastic shrinkage and light cracking in floors and shotcrete. PVA and PAN fibers bond tightly with the concrete and are often used in thin layers or special mixes. UHMWPE fibers are super strong and resistant to chemicals, which makes them good for industrial and marine projects. Polyester fibers perform well in standard jobs. Glass and basalt fibers are strong, resist heat well, and are often used in thin concrete panels. Steel fibers are the go-to option for heavy-duty floors and tunnel linings because they can hold a lot of weight after cracking. Carbon and aramid fibers are for projects where strength and resistance to wear are important. Wood is mostly used in special eco mixes. Ecocretefiber™ covers important types like polypropylene, PVA, PAN, UHMWPE, polyester, glass, basalt, and steel.

1. Polypropylene Fiber

Polypropylene fiber is light, non-corrosive, and ideal for plastic shrinkage control and surface crack reduction. It is cost-effective and easy to dose in ready-mix, precast, and on-site batching.

2. Polyvinyl Alcohol (PVA) Fiber

PVA fiber bonds very strongly with cement paste. It is often used in thin overlays, repair mortars, and engineered cementitious composites that need very tight crack widths.

3. Polyacrylonitrile (PAN) Fiber

PAN fiber offers high tensile strength and good chemical resistance. It is a good choice for industrial floors, tunnels, and elements exposed to aggressive liquids or gases.

4. Ultra-High Molecular Weight Polyethylene (UHMWPE) Fiber

UHMWPE fiber has extremely high strength-to-weight ratio and very low density. It brings excellent impact and abrasion resistance, especially in demanding industrial and marine structures.

5. Polyester Fiber

Polyester fiber improves toughness and fatigue resistance. It works well in slabs-on-ground, pavements, and precast elements that see repeated traffic and vibration.

6. Glass Fiber

Glass fiber is widely used in glass fiber reinforced concrete panels and façade elements. It gives good tensile strength and fire behavior, but it needs alkali-resistant grades for long life.

7. Basalt Fiber

Basalt fiber comes from natural volcanic rock and gives high tensile strength with good chemical and temperature resistance. It is a strong option where durability and environmental image both matter.

8. Steel Fiber

Steel fiber delivers very high flexural toughness and post-crack load capacity. It is often used to replace part of the rebar or mesh in heavy-duty floors, pavements, and tunnel linings.

9. Carbon Fiber

Carbon fiber has very high stiffness and fatigue strength. It is more expensive, so it is mainly used in special projects that need maximum performance with low weight.

10. Aramid Fiber

Aramid fiber is another high-performance type with strong impact and fatigue behavior. It is used in special industrial and defense applications where failure is not acceptable.

11. Wood Fiber

Wood fiber and other plant-based fibers are used in eco-friendly materials and light boards. They reduce density and improve sound and thermal performance in some systems.

12. Flocking Fiber

Flocking fiber usually refers to very fine fibers used to improve surface texture or special properties. They are common in thin toppings, repair mortars, and decorative mixes.

13. Other Special Fibers for Concrete

There are many proprietary blends that mix two or more fiber materials or shapes. Ecocretefiber™ can work with you to design special blends that match your exact project needs.

How to Pick the Right Concrete Fiber?

Some buyers only check the price and ignore performance. This is risky, because the wrong fiber won’t control cracks or carry the weight you need it to.

Pick the right fiber by looking at the project, weight, exposure, and local rules. Then, find a trusted supplier that can match the fiber material, shape, length, and amount to your needs.

Start with the project. For light jobs like house floors etc, focus on stopping plastic shrinkage and improving surface quality. Micro polypropylene fibers are a good choice here. For industrial floors you want fibers that allow larger joint spacing, higher wheel loads and can sustain impacts. In this case, you should look at macro synthetic or steel fibers. If the structure is in a marine or chemical area, corrosion should be considered. In that case, non-rusting macro synthetic fibers work better. Check how the surface will be finished. Some fibers might show a bit, so you may want to pick a finer fiber or adjust your finishing method. Always talk to your engineer to make sure you meet load-bearing rules. Ecocretefiber™ technical staff from Shandong Jianbang Chemical Fiber Co., Ltd. can help you compare options and prepare proposals, so you can be confident you have the right option.

How Much Fiber to Add?

If you don’t add enough fiber, you’re wasting money. If you add too much, it can be hard to work with the concrete. So knowing how much to use is important.

For micro synthetic fibers, you usually need from 0.6 to 1.5 kg per cubic meter of concrete. For macro synthetic and steel fibers, you usually need to add 3 to 6 kg per cubic meter or more.

The amount of fiber depends on what you want the system to do. If you only want to reduce plastic shrinkage cracks and improve durability, lower amounts of micro polypropylene fibers will do. They create a network near the surface and hold cracks tight. If you want the fiber to help with the structure, such as for industrial floors or roads, you’ll need more macro synthetic or steel fibers. The mix also matters. A good mix will help the concrete carry more fiber while still being workable. Always test mixes and beam before you switch from mesh to fiber. Ecocretefiber™ gives suggested amounts for each product and project type.

Can Concrete Fiber Replace Rebar?

A lot of contractors ask this question because they want to save time and effort. Fiber can sometimes replace mesh, but it doesn’t always replace rebar.

Concrete fiber can replace reinforcement that accounts for temperature and shrinkage in many floors. But, for main structural support in beams, you still need rebar, based on structural engineering.

Steel bars and mesh are designed to handle major forces. They sit in specific spots inside the concrete and act as a continuous support. Fibers are spread randomly throughout the concrete. They control cracks well, but they don’t create the same kind of support as bars. In many slabs, parking lots, and industrial floors, engineers now replace mesh with synthetic or steel fiber systems because the main goal is crack control. This saves time cutting, placing, and reduces safety risks on site. However, for suspended slabs, beams, columns, and walls, fiber is usually used with rebar, not instead of it. When you use Ecocretefiber™ products, our team can help you review where fiber-only designs work and where you need a mix of both.

Conclusion

Concrete fiber reinforcement is a simple tool that helps you control cracks and improve strength. When you understand how different fiber materials work, you can pick the right type for each project. By choosing the right material, shape, and amount, you can reduce steel, speed up installation, and give your clients long-lasting floors. Working with a supplier like Ecocretefiber™ means you get technical support and confidence on every job.

Ecocretefiber – Chinese Concrete Fiber Manufacturer

Ecocretefiber™ is the concrete fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. Our factory produces polypropylene, PAN, PVA, UHMWPE, polyester, glass, basalt, and other fibers that cover most concrete applications. We focus on stable quality and fast delivery. Ecocretefiber™ offers standard products and lengths. We support you with advice on mixing and dosage. If you are looking for a supplier, our team is ready to talk and design products with you.