Fiber concrete is another name for fiber reinforced concrete (FRC). It is concrete made with cement, aggregates, and short reinforcing fibers mixed through the batch.

The goal is simple. Fibers help control cracking. They also improve toughness in many mixes. Some fiber types can support durability in aggressive environments.

What is fiber concrete (fiber reinforced concrete)?

Fiber concrete is concrete that contains discrete fibers inside the mix. The fibers spread through the whole volume. They are not installed like steel bars. They are part of the concrete itself.

This matters because concrete tends to crack. It shrinks as it dries. It can crack early when the surface dries fast. It also cracks under load because concrete is weak in tension. Fiber concrete does not “stop all cracks.” It helps keep cracks smaller. It also helps the concrete hold together better after a crack forms.

What fibers are used in fiber concrete?

Fibers for concrete come from several material families. The most common groups are steel fibers, glass fibers, and synthetic polymer fibers.

You may also see natural fibers in some products, especially for low-cost reinforcement needs.

In daily construction work, these categories are common:

- Steel fiber: strong, stiff, good for toughness and residual strength after cracking.

- Synthetic fiber (often polypropylene): light, non-corrosive, widely used for crack control.

- Glass fiber (often alkali-resistant for cement systems): used in thin panels and architectural products.

- High-bond synthetic fibers (such as PVA in certain systems): used when very tight crack width control is needed (common in repair or high-performance cement mixes).

The “best” fiber is not universal. The right choice depends on what problem you want to solve.

How does fiber concrete work?

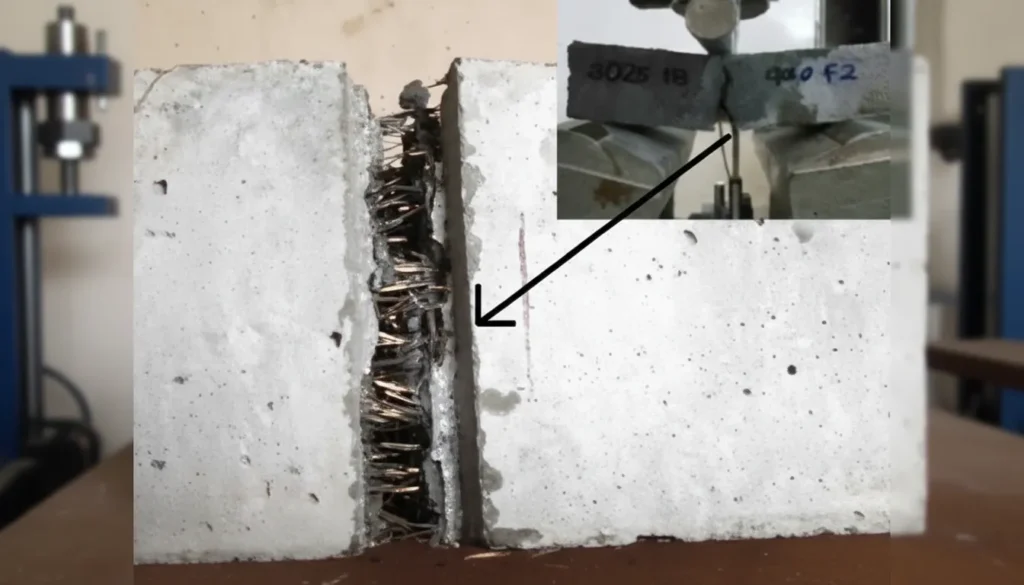

Fiber concrete works mainly through crack bridging.

When concrete starts to crack, the crack tries to open. Fibers crossing the crack resist that opening. This spreads stress over many small bridges instead of one large break. The result is often a tighter crack pattern and better post-crack behavior.

Fiber concrete also behaves differently at different ages:

- Fresh concrete stage: Micro fibers form a small network in the paste. This can reduce plastic shrinkage cracking when the surface dries fast.

- Hardened concrete stage: Larger fibers (macro synthetic or steel) help carry load after first cracking. This improves toughness and residual strength.

In some dense concrete designs, polypropylene micro fibers are used as a fire safety measure because they are recognized as a way to reduce explosive spalling risk in certain tunnel and high-performance concrete cases.

What are the main benefits of fiber concrete?

Fiber concrete is popular because it solves common jobsite problems with one simple change: add fibers during mixing.

Better crack control

Micro fibers are widely used to reduce plastic shrinkage cracking in the first hours after placement.

They can also support plastic settlement control by helping stabilize the mix and limiting bleed water channels (reported in industry discussions of microfibre action).

Better toughness and impact resistance

Macro synthetic fibers or steel fibers can improve toughness. The concrete can hold together longer after cracking. This is valuable for slabs, pavements, and shotcrete systems.

Durability support

Smaller cracks usually mean less water and salt movement through the concrete. That supports durability, especially when corrosion risk is a concern.

Faster construction in some slabs

In some slab-on-ground designs, fibers can reduce or replace light mesh that mainly targets crack control. This can reduce labor on site. The project still needs proper design checks.

What are the limits of fiber concrete?

Fiber concrete has clear limits. If you state them early, you avoid wrong expectations.

- Fibers are not always a replacement for rebar. Rebar provides defined tensile capacity in specific zones. Fibers are distributed. Many structural members still need rebar by code and by design practice.

- Not all fibers add structural strength. Micro synthetic fibers mainly target early-age crack control. They do not turn plain concrete into a fully “reinforced beam.”

- Mixing quality matters. Poor fiber dispersion can reduce performance. Clumping can also create weak spots.

- Finishing can change. Some fiber types, especially macro fibers, can affect finishing feel. Good timing and correct workability solve most issues.

If your project is structural, the safe approach is simple. Follow the engineer’s design. Use fibers as a performance upgrade. Do not use fibers as a shortcut around reinforcement rules.

Where is fiber concrete used?

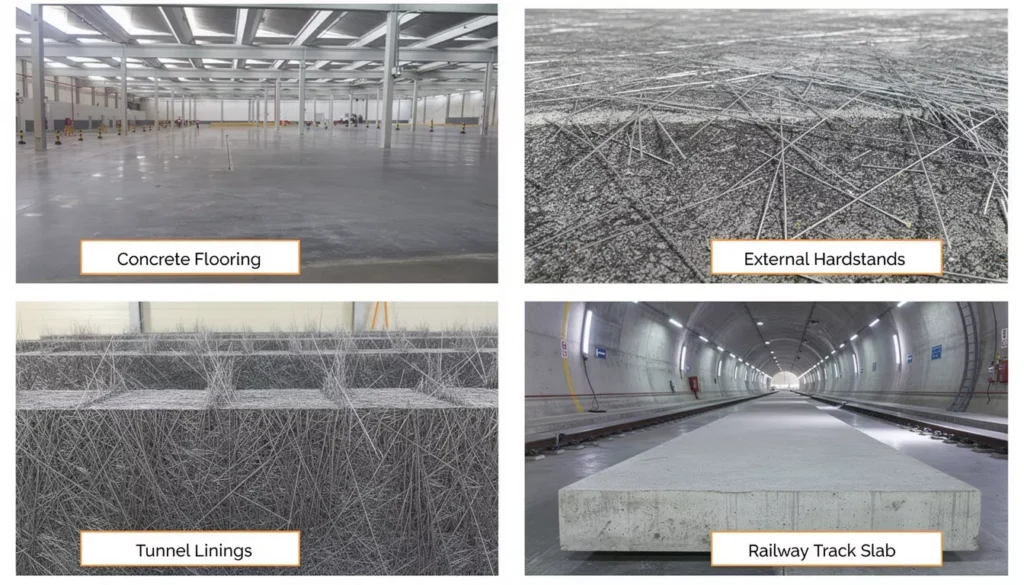

Fiber concrete is used in many segments because it is flexible. Fibers go where concrete goes.

Common applications include:

- Slabs-on-ground: warehouses, logistics floors, workshops, parking areas

- Screeds and toppings: thin layers that dry fast

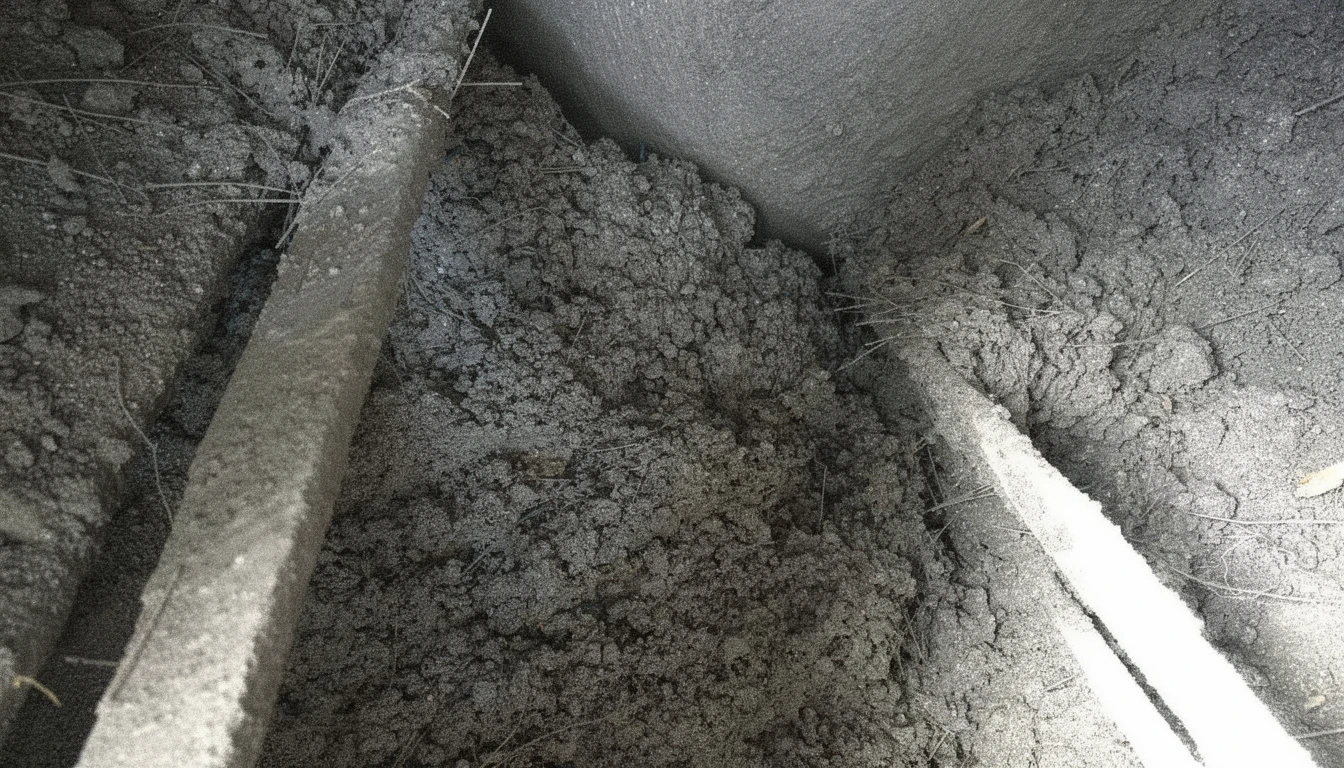

- Shotcrete: tunnels, slopes, repairs, mining support

- Precast products: pipes, covers, panels, channels

- Decorative and thin elements: some systems use specialty fibers for thin sections and improved surface performance

- Tunnel concrete and HPC/UHPC projects: micro PP fibers are often discussed for spalling risk reduction in fire scenarios in specific designs

The best fit is usually a project that needs crack control, toughness, or speed of placement. Fiber concrete is also useful when rebar placement is difficult because of complex shapes or tight working space.

What is a typical dosage for fiber concrete?

Dosage depends on fiber type and the performance target. There is no one number that fits all.

A practical way to think about dosage:

- Micro synthetic fibers (often polypropylene): used for plastic shrinkage crack control. A commonly cited dosage level is around 0.9 kg/m³ in industry discussions of microfibres, with some sources noting this level helps block bleed water channels and support settlement control.

- Structural fiber systems (often steel fibers): dosage is set by design targets and verified by testing, not by a single “rule of thumb.”

Mixing guidance is as important as dosage:

- Add fibers slowly, not all at once.

- Mix long enough to disperse.

- Use water reducers if needed. Avoid adding extra water to “fix” slump.

- Keep curing strict. Fibers help, but curing still drives early crack risk.

What standards and tests are used for fiber concrete?

If you only use micro fibers for plastic shrinkage crack control, many projects rely on supplier guidance and internal trials.

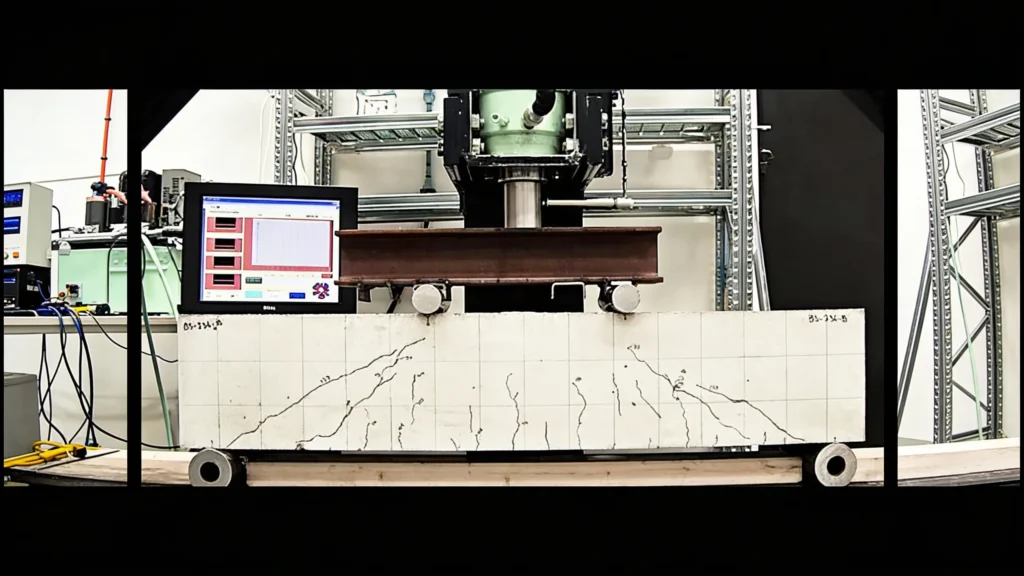

If you use fibers for structural or performance-based claims, testing and standards become critical.

Two widely referenced points:

- EN 14651 is a standard test method used to measure flexural tensile performance and residual strength of metallic fiber reinforced concrete.

- Structural design discussions often reference frameworks such as fib Model Code 2010, which recognizes fiber reinforced concrete as a material for structural use in certain contexts.

In some regions, you will also see local design guides that align testing with accepted design workflows, such as the Singapore-oriented FRC design guide linked to SS 674-2021.

If your goal is to replace mesh or reduce rebar in a slab, you should treat it like a design task. Use test data. Use an accepted method. Document the decision.

Ecocretefiber™: practical support for fiber concrete projects

Fiber concrete works best when product selection is correct, dosage is correct, and mixing is controlled.

Ecocretefiber™ is the fiber brand of Shandong Jianbang Chemical Fiber Co., Ltd. We support fiber concrete projects with product options across common fiber categories, plus practical jobsite guidance.

What we typically support:

- Fiber selection: micro vs macro, plus matching fiber type to the crack problem

- Dosage suggestions based on application, mixing conditions, and target performance

- Mixing and finishing tips to reduce clumping and surface issues

- Documentation support for distributors and project bids

If you want to build a stable fiber concrete product line, we can support long-term supply and technical alignment.

Conclusion

Fiber concrete is concrete that contains short reinforcing fibers distributed through the mix.

It is used to control cracking, improve toughness, and support durability. Some fiber systems also support fire-related spalling risk control in specific dense concrete designs.

The best results come from a simple discipline: choose the right fiber type, verify dosage with trials or tests, then execute mixing and curing properly. If the element is structural, keep rebar where design codes require it, then use fibers as a performance upgrade.