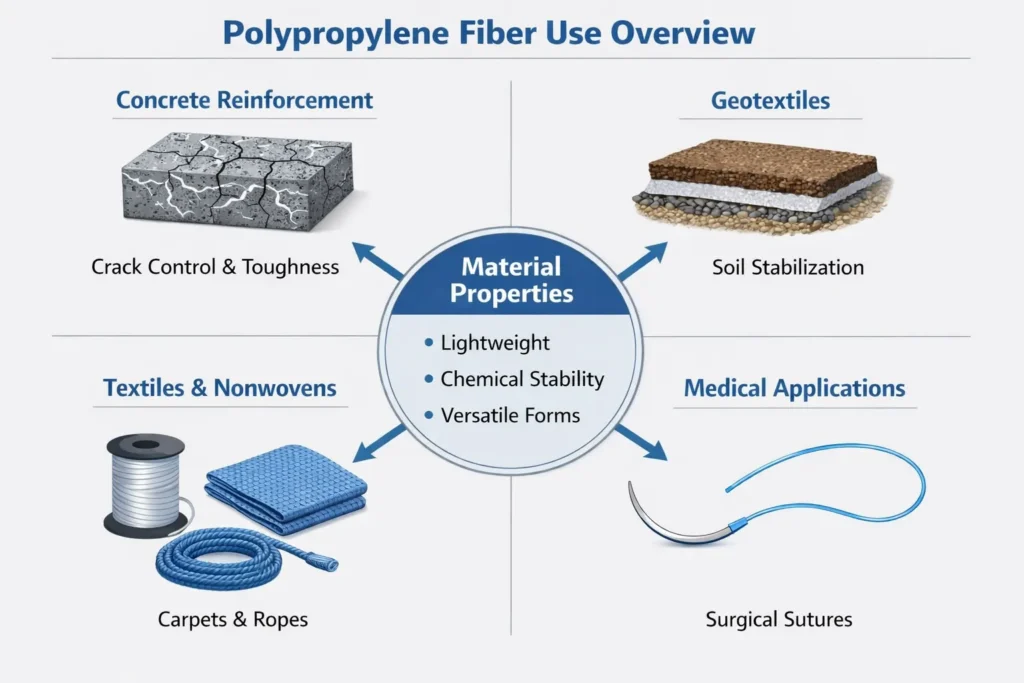

Polypropylene (PP) fiber is used to improve performance in products that need durability, crack control, or lightweight strength. In construction, PP fiber is most common in concrete and mortar. It helps reduce early cracking. It can also improve toughness and impact resistance in the right form. Industry guidance highlights synthetic fibers for shrinkage crack reduction, plus higher energy absorption and impact resistance.

Outside construction, PP fiber is widely used in geotextiles, nonwoven fabrics, ropes, carpets, and some medical devices. It is popular because it resists many chemicals, stays lightweight, and can be made into many fiber forms.

Polypropylene fiber in one minute

Polypropylene fiber is a synthetic fiber made from polypropylene polymer. It can be produced as fine microfibers, thicker macrofibers, yarns, or nonwoven webs. This flexibility is why it shows up in both building materials and textiles.

In concrete work, PP fiber is usually added during mixing. It becomes “distributed reinforcement.” That means many small fibers spread through the whole mix. NRMCA notes synthetic fibers help reduce plastic and drying shrinkage cracking, while improving energy absorption and impact resistance.

Concrete use: plastic shrinkage crack control

One of the most common uses of polypropylene fiber is early crack control in slabs, pavements, and flatwork. Plastic shrinkage cracks form when the surface loses water too fast, before concrete hardens.

Micro polypropylene fibers help in this early window. They give the fresh paste internal support when tensile strength is still low. NRMCA’s guidance on plastic shrinkage cracking recommends considering synthetic fibers (ASTM C1116) to help minimize plastic shrinkage cracking.

TRB research also notes polypropylene fibers became popular because they reduce early-age cracking under restrained plastic shrinkage.

Typical jobsite uses:

- slabs-on-ground for warehouses or workshops

- residential driveways and sidewalks

- overlays and toppings that dry fast

Concrete use: toughness and impact resistance

Polypropylene fiber is also used to improve toughness, especially when the fiber is a macro type. NRMCA describes synthetic fibers as a way to increase energy absorption and resistance to impact forces.

This matters in floors and pavements where the concrete sees wheel loads, abrasion, or repeated hits. Fibers help hold the matrix together after a crack starts. The concrete can stay serviceable longer, even when it is cracked.

Common practical uses:

- industrial floors with forklifts

- yards and hardstands

- joint edges where spalling is costly

- precast items that chip during handling

Concrete use: reducing explosive spalling risk in fire

In dense concrete, heat can build internal vapor pressure during fire. That pressure can trigger explosive spalling. Polypropylene fiber is widely used as a mitigation method, especially in tunnel construction.

A technical paper from Sika’s concrete systems group states PP fibers are increasingly used to inhibit explosive spalling in fire, with tunnel construction as a key driver.

Peer-reviewed literature also reports that adding PP fibers can reduce spalling risk under fire exposure.

The common mechanism is simple. PP fibers melt at elevated temperature. This can create pathways that relieve vapor pressure. That helps reduce spalling risk in certain designs.

Typical uses:

- tunnel linings

- high-strength, low-permeability concrete elements where fire performance is specified

Mortar and plaster use: better crack control and cohesion

Polypropylene fiber is widely used in mortar-based products where shrinkage cracking is common. This includes repair mortars, renders, plasters, and thin toppings.

The value is practical. Microfibers help reduce early cracking in thin sections. They also help the fresh mix stay more stable during placement. Many spec documents describe microfibers mainly as a tool to reduce plastic shrinkage cracking or plastic settlement cracking.

Common uses:

- patch repair mortar

- thin screeds and leveling layers

- plaster or render systems where drying is fast

Shotcrete and precast use: stability, durability, handling performance

In shotcrete, the mix must stay cohesive during pumping and spraying. Fibers can support that stability. In precast, fibers can help reduce edge damage and micro cracking during stripping, lifting, and transport.

Industry guidance describes synthetic fibers as compatible with common mineral additions and admixtures. That helps ready-mix and precast plants integrate fibers without changing the whole system.

Common uses:

- shotcrete for slopes, repairs, tunnel support

- precast utility products

- thin precast pieces where chipping is a complaint driver

Geotextiles use: separation, filtration, drainage, containment

A major non-concrete use of polypropylene fiber is geotextiles. Many nonwoven geotextiles use polypropylene because it performs well in harsh soil and chemical environments.

Solmax notes polypropylene is commonly used in aggressive environments. It highlights nonwoven polypropylene geotextiles as widely used in waste containment applications, with chemical resistance as a key advantage.

Manufacturers also describe nonwoven polypropylene geotextiles as used for separation, filtration, and drainage between soil layers.

Typical civil uses:

- road base separation

- drainage layers

- filtration around pipes

- containment and liner protection in waste facilities

Nonwovens and textiles use: carpets, ropes, hygiene products

A large share of polypropylene is turned into fibers for textiles and nonwovens. Polypropylene fiber is common in indoor-outdoor carpets and upholstery. It is also used in rope and cordage. It is widely used in disposable nonwoven fabrics for hygiene and medical applications.

This is why PP fiber shows up in:

- carpets and rugs

- upholstery fabrics

- rope, cordage, fishing gear

- disposable nonwovens (diapers, medical garments)

If you sell PP fiber into textile channels, buyers often care about colorfastness, abrasion resistance, and process stability more than “concrete-style” performance.

Medical use: polypropylene sutures

Polypropylene is also used in medical sutures as a non-absorbable monofilament option. Ethicon’s PROLENE polypropylene suture is indicated for soft tissue approximation or ligation, including cardiovascular and other surgical uses.

This use is different from construction use, but the driver is similar. Polypropylene stays stable in many environments. It can be made into smooth monofilament fiber, which helps handling for certain procedures.

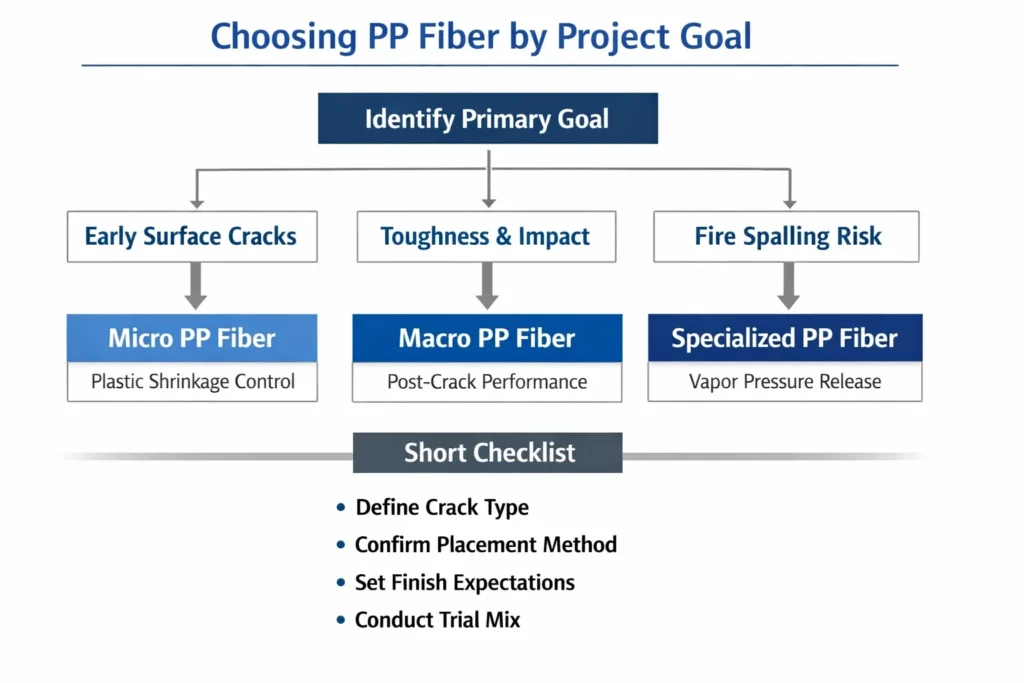

How to choose the right PP fiber for concrete work

If your main market is concrete, selection should start with the failure mode you want to reduce.

If your issue is early surface cracks

Choose micro polypropylene fiber. NRMCA’s plastic shrinkage guidance points to synthetic fibers as a mitigation option.

If your issue is slab toughness or impact

Review macro synthetic PP fibers. Use performance data where the slab design expects post-crack contribution. NRMCA distinguishes higher dosage macro fibers for toughness applications.

If your issue is tunnel fire spalling

Follow the project fire specification. Use documented spalling mitigation guidance. PP fiber is widely discussed for this role in tunnel practice.

A short checklist that reduces mistakes:

- define the crack type you want to reduce

- confirm placement method (slab, pump, shotcrete, precast)

- confirm finish expectations

- follow a trial mix and trial pour

- keep curing discipline, since fibers do not replace curing

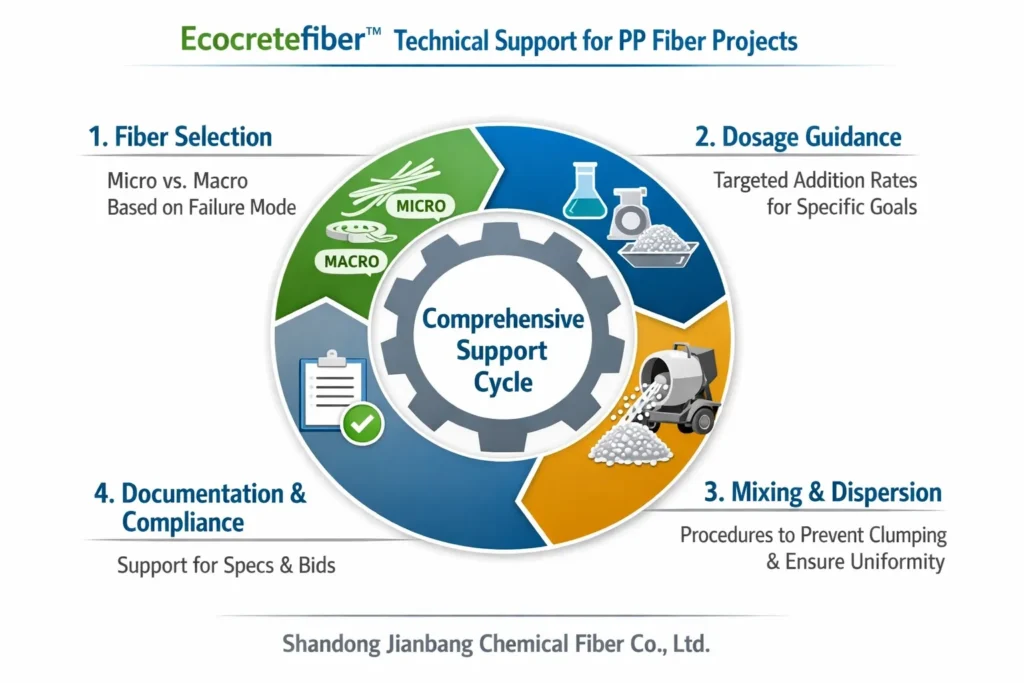

Expert guidance: what good support looks like

Many site issues come from mismatch. The fiber may be correct, but the mixing plan is weak. The dosage may be fine, but workability control is missing. The project may need macro performance, but the crew used micro fiber only.

Good support usually includes:

- fiber selection: micro vs macro

- dosage guidance tied to the problem, not habit

- mixing steps that prevent clumping

- finishing tips that fit the fiber type

- documentation support for specs and bids, including common guidance sources that describe fiber benefits and use cases

Ecocretefiber™ | Shandong Jianbang Chemical Fiber Co., Ltd.

Ecocretefiber™ supplies polypropylene fibers for concrete, including microfiber and macro-synthetic options. We support project matching, dosage suggestions, and practical mixing guidance, then move into stable supply for repeat orders.

Related Products

- Polypropylene Microfiber (Monofilament / Fibrillated)

- Polypropylene Macro-Synthetic Fiber

- PVA Fiber for Cement-Based Composites

- AR Glass Fiber for GRC Systems

Conclusion

Polypropylene fiber is used in many industries because it is lightweight, stable, and easy to form into different fiber products. In concrete, it is widely used to reduce early cracking, improve toughness, and support impact resistance. Industry guidance also highlights synthetic fibers for shrinkage crack reduction, plus higher energy absorption.

In dense concrete exposed to fire, PP fiber is also used to reduce explosive spalling risk in many tunnel projects.

Outside construction, polypropylene fiber is common in geotextiles, plus textile and nonwoven applications such as carpets, ropes, and disposable fabrics.